** SOLD **

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

about a similar one

- Machine Code

- EX516

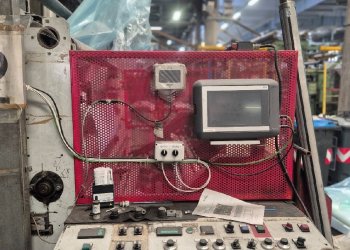

- Manufacturer

- MACCHI

- Modello

- ( COEX )

- Year

- 2006

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE

- Film Width

- 1700

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 65mm

- Description 1

- L/D30 Plastex . Motor ac KW74

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 80mm

- Description 2

- L/D30 Plastex . Motor ac KW100

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 65mm

- Description 3

- L/D30 Plastex . Motor ac KW74

- Head description

- IBC GET 6 system. Cooling ring. Fixed die head Coex flex TE 502. Gap 1,6mm

- Die diam (mm)

- 300

- Thickness controll system

- Kunding

- Panel for gussets

- No

- Web guide

- E&L automatic

| Machine Code | EX516 |

| Manufacturer | MACCHI |

| Modello | ( COEX ) |

| Year | 2006 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE |

| Film Width | 1700 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 65mm |

| Description 1 | L/D30 Plastex . Motor ac KW74 |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 80mm |

| Description 2 | L/D30 Plastex . Motor ac KW100 |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 65mm |

| Description 3 | L/D30 Plastex . Motor ac KW74 |

| Head description | IBC GET 6 system. Cooling ring. Fixed die head Coex flex TE 502. Gap 1,6mm |

| Die diam (mm) | 300 |

| Thickness controll system | Kunding |

| Panel for gussets | No |

| Web guide | E&L automatic |

WINDMÖLLER & HÖLSCHER Optimex

-

Machine Code: EX792

-

Year: 2011

-

Film Width: 1800

WINDMÖLLER & HÖLSCHER VAREX

-

Machine Code: EX744

-

Year: 2002

-

Film Width: 2100

BIELLONI 100

-

Machine Code: EX787

-

Year: 2001

-

Film Width: 1800