Raw material most commonly used are low density polyethylene (LDPE) and High density polyethylene (HDPE). These are often used in blends with other polymers and additives.

Ask more informations

- Machine Code

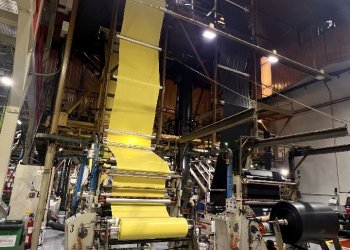

- EX717

- Manufacturer

- BIELLONI

- Year

- 1998

- Number of layers

- 1

- Film structure

- Blends

- Material

- LDPE for heavy duty sacks

- Film Width

- 1200

- Output (Kg/h)

- 150

- Extruder 1 Layer ref:

- 80 LD30

- Screw diam 1

- 80mm

- Description 1

- manual screenrchanger

- Die diam (mm)

- 200

- Thickness controll system

- By touching element

- Bubble cage

- Yes

- Panel for gussets

- Yes

- Take off unit

- Oscillating

- Corona treatment

- Cason

- Web guide

- Yes

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1000

- Note

- Two cooling rings, one for tubulars and one for films Gravimetric system Contrex Corona treater Cason.

| Machine Code | EX717 |

| Manufacturer | BIELLONI |

| Year | 1998 |

| Number of layers | 1 |

| Film structure | Blends |

| Material | LDPE for heavy duty sacks |

| Film Width | 1200 |

| Output (Kg/h) | 150 |

| Extruder 1 Layer ref: | 80 LD30 |

| Screw diam 1 | 80mm |

| Description 1 | manual screenrchanger |

| Die diam (mm) | 200 |

| Thickness controll system | By touching element |

| Bubble cage | Yes |

| Panel for gussets | Yes |

| Take off unit | Oscillating |

| Corona treatment | Cason |

| Web guide | Yes |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1000 |

| Note | Two cooling rings, one for tubulars and one for films Gravimetric system Contrex Corona treater Cason. |

TECOM EKN90-30D

-

Machine Code: EX790

-

Year: 1993

-

Film Width: 1800

REIFENHAUSER

-

Machine Code: EX637

-

Year: 2002

-

Film Width: 1800

GHIOLDI - BANDERA

-

Machine Code: EX569

-

Year: 1990

-

Film Width: 1400

REIFENHAUSER

-

Machine Code: EX808

-

Year: 2022

-

Film Width: 1800