Raw material most commonly used are low density polyethylene (LDPE) and High density polyethylene (HDPE). These are often used in blends with other polymers and additives.

Ask more informations

- Machine Code

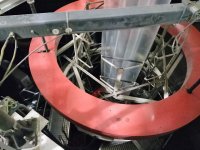

- EX792

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- Optimex

- Year

- 2011

- Number of layers

- 3

- Film structure

- ABC

- Film Width

- 1800

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 60

- Description 1

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 90

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 60

- Thickness controll system

- yes automatic

- Rewinder Type

- Single winder

| Machine Code | EX792 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | Optimex |

| Year | 2011 |

| Number of layers | 3 |

| Film structure | ABC |

| Film Width | 1800 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 60 |

| Description 1 | |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 90 |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 60 |

| Thickness controll system | yes automatic |

| Rewinder Type | Single winder |

TECNOVA ES90B / 30D

-

Machine Code: EX789

-

Year: 2020

-

Film Width: 1800

KUNG HSING KS-MH50+55/380V- 50HZ

-

Machine Code: EX768

-

Year: 2018

-

Film Width: 1200