** SOLD **

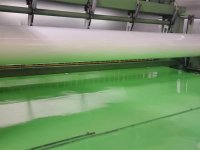

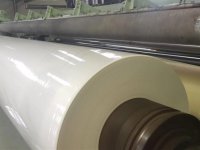

Biaxially oriented polypropylene (BOPP) and Biaxially oriented polyester (BOPET) are commonly produced in tender-frame lines. In these lines material is melted through a flat extrusion die (T-die) and solidified onto a cooled roller. Material is then stretched in machine direction in an MDO. Thereafter material is stretched in transversal direction in a TDO. These processes deliver a molecule orientation in both axes, this enhances many of their properties, particularly the mechanical, impact, barrier and optical properties.

Ask more informations

about a similar one

- Machine Code

- BO75

- Manufacturer

- MITSUBISHI

- Year

- 2003

- Number of layers

- 3

- Film structure

- ABC

- Material

- BOPP

- Output

- on 15my BOPP 340m/min, on 28my BOPP tape film 320 m/min

- Width (mm)

- 8300

- Rewinder description

- Turret type

- Slitter

- Goebel Monslit. 10x couples of winding arms. Driven position of knives and arms.

| Machine Code | BO75 |

| Manufacturer | MITSUBISHI |

| Year | 2003 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | BOPP |

| Output | on 15my BOPP 340m/min, on 28my BOPP tape film 320 m/min |

| Width (mm) | 8300 |

| Rewinder description | Turret type |

| Slitter | Goebel Monslit. 10x couples of winding arms. Driven position of knives and arms. |

MITSUBISHI

-

Machine Code: BO102

-

Year: 2001

-

Width (mm): 4200

BRUCKNER TOSHIBA

-

Machine Code: BO105

-

Year: 1994

-

Width (mm): 5600

DORNIER TOSHIBA

-

Machine Code: BO93

-

Year: 2012

-

Width (mm): 5100