These employ an interchangeable trolley system which allows different types of coatings or laminations depending on available trolleys.

Ask more informations

- Machine Code

- LA512

- Manufacturer

- NORDMECCANICA

- Modello

- TRIPLEX COMBI

- Year

- 1994

- Application

- Triplex lamination

- Type of lamination/coating

- COMBI / INTECHANGEABLE TROLLEY

- Overhaul/renovation

- 2023 new control cabinets with new PLC and Drives. Machine had various mechanical maintenances and upgrades in recent years. Corona treatments, LEL system

- Working width (mm)

- 1280

- Materials

- Films, paper all foil

- Speed

- 300 m/min

- First unwinder type

- Turret

- Max diameter reel unwinder

- 900

- Secondary unwinder type

- Turret

- Max diameter reel unwinder

- 900

- Third unwinder type

- Turret

- Max diameter reel unwinder

- 900

- Rewinder type

- Turret

- Max diameter reel rewinder

- 1000

- Coating unit

- Interchangeable trolley system. Available with gravure trolley

- Second Coating unitr

- Interchangeable trolley system. Available with gravure trolley and with solvent less trolley

- Drying

- First coating unit with double vertical drying hoods. Second coating unit with double vertical drying hoods. Each Hood (4) with independent ventilation and heaters

- Register controll

- Yes on second unit

- pumping mixing unit

- 2 components pumping mix unit for solvent less

- Corona treatment

- 2 Corona Vetaphone

- Note

- - LEL make Operational mod FTA - PLC: ALLEN-BRADLEY - Turning bar between coating units

| Machine Code | LA512 |

| Manufacturer | NORDMECCANICA |

| Modello | TRIPLEX COMBI |

| Year | 1994 |

| Application | Triplex lamination |

| Type of lamination/coating | COMBI / INTECHANGEABLE TROLLEY |

| Overhaul/renovation | 2023 new control cabinets with new PLC and Drives. Machine had various mechanical maintenances and upgrades in recent years. Corona treatments, LEL system |

| Working width (mm) | 1280 |

| Materials | Films, paper all foil |

| Speed | 300 m/min |

| First unwinder type | Turret |

| Max diameter reel unwinder | 900 |

| Secondary unwinder type | Turret |

| Max diameter reel unwinder | 900 |

| Third unwinder type | Turret |

| Max diameter reel unwinder | 900 |

| Rewinder type | Turret |

| Max diameter reel rewinder | 1000 |

| Coating unit | Interchangeable trolley system. Available with gravure trolley |

| Second Coating unitr | Interchangeable trolley system. Available with gravure trolley and with solvent less trolley |

| Drying | First coating unit with double vertical drying hoods. Second coating unit with double vertical drying hoods. Each Hood (4) with independent ventilation and heaters |

| Register controll | Yes on second unit |

| pumping mixing unit | 2 components pumping mix unit for solvent less |

| Corona treatment | 2 Corona Vetaphone |

| Note | - LEL make Operational mod FTA - PLC: ALLEN-BRADLEY - Turning bar between coating units |

CUSTOM MADE

-

Machine Code: LA488

-

Year: 1991

-

Working width (mm): 2946

NORDMECCANICA SUPERSIMPLEX

-

Machine Code: LA304

-

Year: 1996

-

Working width (mm): 1400

BIELLONI Julia II

-

Machine Code: LA461

-

Year: 1998

-

Working width (mm): 1400

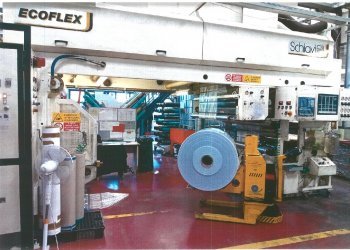

SCHIAVI ECOFLEX

-

Machine Code: LA378

-

Year: 2000

-

Working width (mm): 1420

NORDMECCANICA Super Simplex 1500

-

Machine Code: LA501

-

Year: 2004

-

Working width (mm): 1500

NORDMECCANICA SIMPLEX L 1300

-

Machine Code: LA483

-

Year: 2000

-

Working width (mm): 1300