A Vacuum metallizer is used to coat a layer of aluminium (or other metals) onto a web, typically plastic film or paper.

Ask more informations

- Machine Code

- ME104

- Manufacturer

- BOBST

- Modello

- K5000

- Year

- 2007

- Working width (mm)

- 2850

- Materials

- BOPP 10 to 50 µm; PET 8 to 20 µm

- Speed

- 1000m/min

- Max diameter reel unwinder

- 1200mm, shaftless chucking system

- Max diameter reel rewinder

- 1200mm, shaftless chucking system

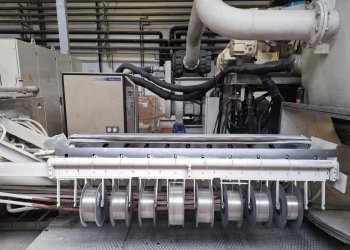

- Evapouration Boots

- - 30 Dimensions: 125 mm x 40 mm x 10 mm, Fully staggered. Aluminium wire specification: Diameter 2 mm, Purity 99.8%

- Pumping down time

- Operating pressure 5 x 10-4 mbar (web coating zone) , Pumping time <5 min (clean, dry and empty)

- Pumping system

- Web coating zones: 1 x SV750 rotary vane pumps, each with a pumping capacity of 750 m3/hr, are employed to evacuate the web coating zone. Each SV750 is purged via automatic gas ballast. 1 x x Aerzen GLB14.9 booster pump, with a pumping capacity of 3,900 m3/hr, is employed to evacuate the web coating zone. 2 x Varian HS35 diffusion pumps, each with a pumping capacity of 50,000 litre/sec, are employed to evacuate the web coating zone. Web winding zone 2 x SV750 rotary vane pumps, each with a pumping capacity of 750 m3/hr, are employed to evacuate the web winding zone. Each SV750 is purged via automatic gas ballast. 2 x Aerzen GLB14.9 booster pump, with a pumping capacity of 3,900 m3/hr, is employed to evacuate the web winding zone. 1 x Aerzen with raised 40 kW motor, with a pumping capacity of 13,000 m3/hr, is employed to evacuate the web winding zone.

- Polycold

- 2 x Polycold PFC 1101 HC cryogenic units, with a total pumping capacity of 400,000 litre/sec, is employed to evacuate the web coating zone. 1 x Polycold PFC 1101 HC cryogenic unit, with a pumping capacity of 200,000 litre/sec, is employed to evacuate the web winding zone.

- Note

- Installed power per evaporator 13 V, 1000 A Power consumption: Average during cycle 350 kW Standby 80 kW PLC software - Siemens S7

| Machine Code | ME104 |

| Manufacturer | BOBST |

| Modello | K5000 |

| Year | 2007 |

| Working width (mm) | 2850 |

| Materials | BOPP 10 to 50 µm; PET 8 to 20 µm |

| Speed | 1000m/min |

| Max diameter reel unwinder | 1200mm, shaftless chucking system |

| Max diameter reel rewinder | 1200mm, shaftless chucking system |

| Evapouration Boots | - 30 Dimensions: 125 mm x 40 mm x 10 mm, Fully staggered. Aluminium wire specification: Diameter 2 mm, Purity 99.8% |

| Pumping down time | Operating pressure 5 x 10-4 mbar (web coating zone) , Pumping time <5 min (clean, dry and empty) |

| Pumping system | Web coating zones: 1 x SV750 rotary vane pumps, each with a pumping capacity of 750 m3/hr, are employed to evacuate the web coating zone. Each SV750 is purged via automatic gas ballast. 1 x x Aerzen GLB14.9 booster pump, with a pumping capacity of 3,900 m3/hr, is employed to evacuate the web coating zone. 2 x Varian HS35 diffusion pumps, each with a pumping capacity of 50,000 litre/sec, are employed to evacuate the web coating zone. Web winding zone 2 x SV750 rotary vane pumps, each with a pumping capacity of 750 m3/hr, are employed to evacuate the web winding zone. Each SV750 is purged via automatic gas ballast. 2 x Aerzen GLB14.9 booster pump, with a pumping capacity of 3,900 m3/hr, is employed to evacuate the web winding zone. 1 x Aerzen with raised 40 kW motor, with a pumping capacity of 13,000 m3/hr, is employed to evacuate the web winding zone. |

| Polycold | 2 x Polycold PFC 1101 HC cryogenic units, with a total pumping capacity of 400,000 litre/sec, is employed to evacuate the web coating zone. 1 x Polycold PFC 1101 HC cryogenic unit, with a pumping capacity of 200,000 litre/sec, is employed to evacuate the web winding zone. |

| Note | Installed power per evaporator 13 V, 1000 A Power consumption: Average during cycle 350 kW Standby 80 kW PLC software - Siemens S7 |

LEYBOLD Topmet 2050

-

Machine Code: ME096

-

Year: 2012

-

Working width (mm): 2400

BOBST K5000

-

Machine Code: ME101

-

Year: 2014

-

Working width (mm): 2450

BOBST K4000

-

Machine Code: ME098

-

Year: 2009

-

Working width (mm): 2450

GENERAL VACUUM EQUIPMENT K2450

-

Machine Code: ME086

-

Year: 2003

-

Working width (mm): 2450

GALILEO V316/P

-

Machine Code: ME097

-

Year: 2000

-

Working width (mm): 1650

GENERAL VACUUM EQUIPMENT EHF 1650

-

Machine Code: ME103

-

Year: 1994

-

Working width (mm): 1650