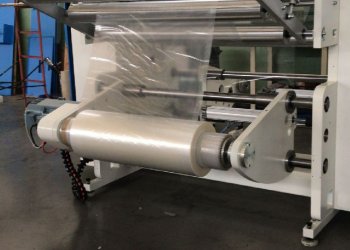

Typical application for flexible packaging are solventless laminators which employ a 2 component glue. Dry and wet bond laminators use solvent base or water based glues. In flexible packaging industry are also common , so called, combi machines.

Ask more informations

- Machine Code

- LA481

- Manufacturer

- UTECO

- Modello

- Horizon D/TH

- Year

- 2005

- Application

- Duplex lamination

- Type of lamination/coating

- SOLVENT / WATER BASED

- Overhaul/renovation

- Upgrades done to PLC, web guides and operator control panel

- Working width (mm)

- 1320

- Materials

- PET, BOPP, CPP, ALU foil, LLDPE, papers

- Speed

- 300m/min

- First unwinder type

- Turret

- Max diameter reel unwinder

- 1000

- Secondary unwinder type

- Turret

- Max diameter reel unwinder

- 1000

- Rewinder type

- Turret

- Max diameter reel rewinder

- 800

- Coating unit

- Gravure coating unit with 2 roll and chamer system

- Drying

- two-zone drying system, both 4 meter long each, each has 2 fans. Each gas burner is rated for 200,000 Kcal/h

- Corona treatment

- Enercon treater at unwind and rewind (two treaters)

- Note

- Spare anilox, brand new doctor blade chamber and spare safety chucks Flying splice on all turrets

| Machine Code | LA481 |

| Manufacturer | UTECO |

| Modello | Horizon D/TH |

| Year | 2005 |

| Application | Duplex lamination |

| Type of lamination/coating | SOLVENT / WATER BASED |

| Overhaul/renovation | Upgrades done to PLC, web guides and operator control panel |

| Working width (mm) | 1320 |

| Materials | PET, BOPP, CPP, ALU foil, LLDPE, papers |

| Speed | 300m/min |

| First unwinder type | Turret |

| Max diameter reel unwinder | 1000 |

| Secondary unwinder type | Turret |

| Max diameter reel unwinder | 1000 |

| Rewinder type | Turret |

| Max diameter reel rewinder | 800 |

| Coating unit | Gravure coating unit with 2 roll and chamer system |

| Drying | two-zone drying system, both 4 meter long each, each has 2 fans. Each gas burner is rated for 200,000 Kcal/h |

| Corona treatment | Enercon treater at unwind and rewind (two treaters) |

| Note | Spare anilox, brand new doctor blade chamber and spare safety chucks Flying splice on all turrets |

NORDMECCANICA TRIPLEX COMBI

-

Machine Code: LA388

-

Year: 1998

-

Working width (mm): 1400

GENERAL CONVERTING MACHINES

-

Machine Code: LA490

-

Year: 2014

-

Working width (mm): 1400

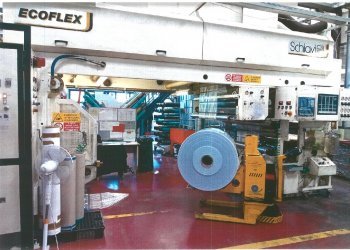

SCHIAVI ECOFLEX

-

Machine Code: LA378

-

Year: 2000

-

Working width (mm): 1420

MB HOT MELT, WAX COATER LAMINATOR

-

Machine Code: LA356

-

Year: 2002

-

Working width (mm): 1700

CML MIRACH

-

Machine Code: LA361

-

Year: 2001

-

Working width (mm): 1250

CML MIRACH

-

Machine Code: LA453

-

Year: 2004

-

Working width (mm): 1300