Typical application for flexible packaging are solventless laminators which employ a 2 component glue. Dry and wet bond laminators use solvent base or water based glues. In flexible packaging industry are also common , so called, combi machines.

Ask more informations

- Machine Code

- LA356

- Manufacturer

- MB

- Modello

- HOT MELT, WAX COATER LAMINATOR

- Year

- 2002

- Application

- Lamination + coating

- Type of lamination/coating

- COMBI / INTECHANGEABLE TROLLEY

- Working width (mm)

- 1700

- Materials

- Paper and board, Film and Alu foil ( secondary unwi)

- Speed

- 400 mpm

- First unwinder type

- Single position shaftless double brake

- Max diameter reel unwinder

- 1600

- Secondary unwinder type

- Single position shaftles

- Max diameter reel unwinder

- 1200

- Rewinder type

- Surface driven shaftless

- Max diameter reel rewinder

- 1900

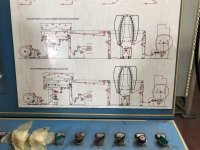

- Coating unit

- Trolley design, available trolleys: - Semi flexo - hot melt/wax with Wax - Hot melt trolley and Semi flexo trolley 3 meter tunnel with one blowing and one exhaus fan and one gas burner for lamination unit with semiflexo trolley

- Second Coating unitr

- - Type direct gravure - 2x drying tunnels 4 m length ( tot 8 m) with independent ventilation - 2 x gas burners, 2 x in blowers, 1 x suction blower. - Automatic recirculation with Nira LEL control - Coating rollers 30,70,80,280 lines/cm

- pumping mixing unit

- Premelting unit Nordson for Wax coating

- Coating rollers

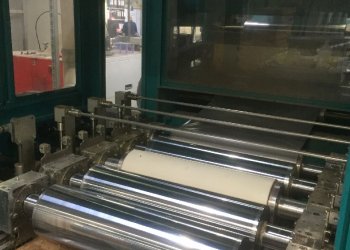

- 6 anilox rollers and 40 sleeves for gravure coating nip roll

- Note

- Possible operation 1) Wax Coating laminating Paper - Alu foil or paper film and primer in line 2) Wax paper coating one side or doiuble side 3) Hot melt coating 4) Water based lamination wet bond paper -Alu foil with semiflexo trolley and primer in line 5) Water based lamination + costing or lacquering

| Machine Code | LA356 |

| Manufacturer | MB |

| Modello | HOT MELT, WAX COATER LAMINATOR |

| Year | 2002 |

| Application | Lamination + coating |

| Type of lamination/coating | COMBI / INTECHANGEABLE TROLLEY |

| Working width (mm) | 1700 |

| Materials | Paper and board, Film and Alu foil ( secondary unwi) |

| Speed | 400 mpm |

| First unwinder type | Single position shaftless double brake |

| Max diameter reel unwinder | 1600 |

| Secondary unwinder type | Single position shaftles |

| Max diameter reel unwinder | 1200 |

| Rewinder type | Surface driven shaftless |

| Max diameter reel rewinder | 1900 |

| Coating unit | Trolley design, available trolleys: - Semi flexo - hot melt/wax with Wax - Hot melt trolley and Semi flexo trolley 3 meter tunnel with one blowing and one exhaus fan and one gas burner for lamination unit with semiflexo trolley |

| Second Coating unitr | - Type direct gravure - 2x drying tunnels 4 m length ( tot 8 m) with independent ventilation - 2 x gas burners, 2 x in blowers, 1 x suction blower. - Automatic recirculation with Nira LEL control - Coating rollers 30,70,80,280 lines/cm |

| pumping mixing unit | Premelting unit Nordson for Wax coating |

| Coating rollers | 6 anilox rollers and 40 sleeves for gravure coating nip roll |

| Note | Possible operation 1) Wax Coating laminating Paper - Alu foil or paper film and primer in line 2) Wax paper coating one side or doiuble side 3) Hot melt coating 4) Water based lamination wet bond paper -Alu foil with semiflexo trolley and primer in line 5) Water based lamination + costing or lacquering |

NORDMECCANICA SIMPLEX COMBI

-

Machine Code: LA336

-

Year: 1996

-

Working width (mm): 1300

Coatema

-

Machine Code: LA469

-

Year: 2017

-

Working width (mm): 700

NORDMECCANICA SUPER SIMPLEX SL HD

-

Machine Code: LA493

-

Year: 2014

-

Working width (mm): 1315

Energy Science INC EC 95/120/600

-

Machine Code: LA489

-

Year: 2011

-

Working width (mm): 1250

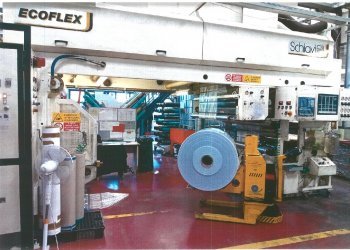

SCHIAVI ECOFLEX

-

Machine Code: LA378

-

Year: 2000

-

Working width (mm): 1420

NORDMECCANICA

-

Machine Code: LA500

-

Year: 1999

-

Working width (mm): 1300