** SOLD **

Raw material most commonly used are low density polyethylene (LDPE) and High density polyethylene (HDPE). These are often used in blends with other polymers and additives.

Ask more informations

about a similar one

- Machine Code

- EX688

- Manufacturer

- MACCHI

- Year

- 2015

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE, LLDPE, MDPE, HDPE (in blends)

- Film Width

- 2100

- Output (Kg/h)

- 600

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 65mm

- Description 1

- L/D30; Screw rpm: 0-170; AC motor 86KW, 4 heating zones, leverage screen changer, Gravimetric mixer 4 componentsDOTECO type Adroit with resin vacuum loaders

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 105mm

- Description 2

- L/D 30; Screw rpm: 0-110; AC motor 180KW, 5 heating zones, leverage screen changer, Gravimetric mixer 4 components DOTECO type Adroit with resin vacuum loaders

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 65mm

- Description 3

- L/D 30; Screw rpm: 0-170; AC motor 86KW, 4 heating zones, leverage screen changer, Gravimetric mixer 4 components DOTECO type Adroit with resin vacuum loaders

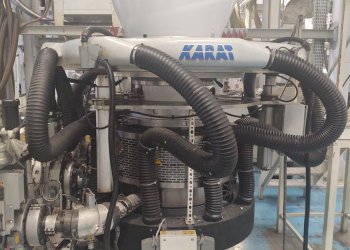

- Head description

- Extrusion head Coex flex, dierange possibility 350-500mm Automatci air rink KARAT COM 3 with automatic thickness profile control; IBC JET 7 ultrasonic control 2 fans 18KW each

- Die diam (mm)

- 400mm diam; 1,2mm gap

- Bubble cage

- 4 Ultrasonic sensor for diameter, sensor for bouble breaks; bouble cage non marking 5+2 levels 8 arms each

- Take off unit

- Rotating 360 deg, cylinder width 2200mm, web width 2100mm, collapsing panels either with carbon fiber rollers or with wooden bars, double S shape cooling calander;

- Corona treatment

- CASON

- Web guide

- E+L

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1200mm

- Rewinder description

- Type BO-PLUS, possibility of reverse winding (both direction winding) with Easy load; in line slitting, laser for cores position, , Antistatic bar SIMCO, 76 mm shafts in steel, 152mm shafts in alluminum

- Note

- Mechanical speed: 7-150 m/min Tower included, height approx 15m Pulling calender between take off and winder Chiller included

| Machine Code | EX688 |

| Manufacturer | MACCHI |

| Year | 2015 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE, LLDPE, MDPE, HDPE (in blends) |

| Film Width | 2100 |

| Output (Kg/h) | 600 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 65mm |

| Description 1 | L/D30; Screw rpm: 0-170; AC motor 86KW, 4 heating zones, leverage screen changer, Gravimetric mixer 4 componentsDOTECO type Adroit with resin vacuum loaders |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 105mm |

| Description 2 | L/D 30; Screw rpm: 0-110; AC motor 180KW, 5 heating zones, leverage screen changer, Gravimetric mixer 4 components DOTECO type Adroit with resin vacuum loaders |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 65mm |

| Description 3 | L/D 30; Screw rpm: 0-170; AC motor 86KW, 4 heating zones, leverage screen changer, Gravimetric mixer 4 components DOTECO type Adroit with resin vacuum loaders |

| Head description | Extrusion head Coex flex, dierange possibility 350-500mm Automatci air rink KARAT COM 3 with automatic thickness profile control; IBC JET 7 ultrasonic control 2 fans 18KW each |

| Die diam (mm) | 400mm diam; 1,2mm gap |

| Bubble cage | 4 Ultrasonic sensor for diameter, sensor for bouble breaks; bouble cage non marking 5+2 levels 8 arms each |

| Take off unit | Rotating 360 deg, cylinder width 2200mm, web width 2100mm, collapsing panels either with carbon fiber rollers or with wooden bars, double S shape cooling calander; |

| Corona treatment | CASON |

| Web guide | E+L |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1200mm |

| Rewinder description | Type BO-PLUS, possibility of reverse winding (both direction winding) with Easy load; in line slitting, laser for cores position, , Antistatic bar SIMCO, 76 mm shafts in steel, 152mm shafts in alluminum |

| Note | Mechanical speed: 7-150 m/min Tower included, height approx 15m Pulling calender between take off and winder Chiller included |

REIFENHAUSER

-

Machine Code: EX686

-

Year: 2003

-

Film Width: 2300

BIELLONI 100

-

Machine Code: EX787

-

Year: 2001

-

Film Width: 1800