** SOLD **

Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

about a similar one

- Machine Code

- CA182

- Manufacturer

- COLINES

- Modello

- Air bubble line

- Year

- 1992

- Number of layers

- 3

- Film structure

- 25/50/25 %

- Material

- Air bubble film

- Film width (mm)

- 2500

- Extruder 1 Layer ref:

- 100mm LD28mm

- Screw diam 1

- 100

- Description 1

- with granule feeding hopper. 3 Lever type screen changers for extruders diam.100 mm

- Extruder 2 Layer ref:

- 100mm LD28mm

- Extruder 3 Layer ref:

- 100mm LD28mm

- Die width (mm)

- 2800

- Rewinder description

- 3-shaft automatic winding unit complete with edge trim cutting, haul-off calender, cylinders

- Note

- N.1 2-position unwinding group for third layer unit complete with disk braking with safety casing N.1 2-position unwinding group for fourth layer unit complete with disk braking with safety casing N.1 Bubble forming calender with cast cylinder and 2 preheating cylinders, vacuum suction pump with forming cylinder diam. 10x4 mm N.1 Chill roll unit with 2 cylinders diam 600 mm and 350 mm N.1 Air blade group N.1 Edge trim recovery system with suction heads, fan with ejector and sound proofing, sound proof mill with suction from grid, air-trim separation cyclone, motorised re-feeding extruder. • Power supply 380V 3-phase 50 Hz+N+G • Installed total power 760 Kw • Required water hardness 20°F • Compressed air quality dry • Compressed air pressure 8 bar

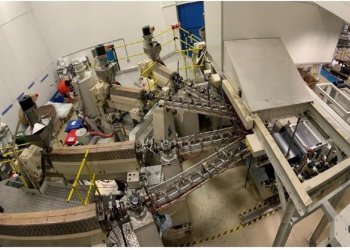

| Machine Code | CA182 |

| Manufacturer | COLINES |

| Modello | Air bubble line |

| Year | 1992 |

| Number of layers | 3 |

| Film structure | 25/50/25 % |

| Material | Air bubble film |

| Film width (mm) | 2500 |

| Extruder 1 Layer ref: | 100mm LD28mm |

| Screw diam 1 | 100 |

| Description 1 | with granule feeding hopper. 3 Lever type screen changers for extruders diam.100 mm |

| Extruder 2 Layer ref: | 100mm LD28mm |

| Extruder 3 Layer ref: | 100mm LD28mm |

| Die width (mm) | 2800 |

| Rewinder description | 3-shaft automatic winding unit complete with edge trim cutting, haul-off calender, cylinders |

| Note | N.1 2-position unwinding group for third layer unit complete with disk braking with safety casing N.1 2-position unwinding group for fourth layer unit complete with disk braking with safety casing N.1 Bubble forming calender with cast cylinder and 2 preheating cylinders, vacuum suction pump with forming cylinder diam. 10x4 mm N.1 Chill roll unit with 2 cylinders diam 600 mm and 350 mm N.1 Air blade group N.1 Edge trim recovery system with suction heads, fan with ejector and sound proofing, sound proof mill with suction from grid, air-trim separation cyclone, motorised re-feeding extruder. • Power supply 380V 3-phase 50 Hz+N+G • Installed total power 760 Kw • Required water hardness 20°F • Compressed air quality dry • Compressed air pressure 8 bar |

PRIMPLAST

-

Machine Code: CA152

-

Year: 1999

-

Film width (mm): 2000

COLINES

-

Machine Code: CA272

-

Year: 2012

-

Film width (mm): 1000

QUANZHOU MINMETALS

-

Machine Code: CA249

-

Year: 2010

-

Film width (mm): 1600