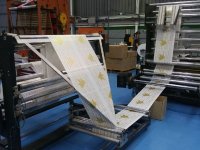

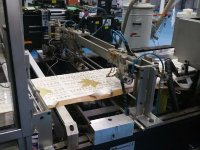

Film bag making machines are used to weld a web or a tubular of plastic film, typically PE or PP, into bags. Their construction and equipment may be very different depending on: the type of bags they need to produce, the type of handle they can apply and the way in which these bags are delivered.

Ask more informations

- Machine Code

- FI521

- Manufacturer

- DE BERNARDI

- Modello

- DB100N SH

- Year

- 2007

- Type of delivery

- Conveyor table

- Type of handle

- Multiple (patch and softloop)

- Type of sealing/bags

- Side weld

- Type of bags

- Soft loop handles

- Working width (mm)

- 850

- Number of lanes

- 1

- Bag length

- 250-800

- Bag width

- 250-800

- Cycle / min

- 100-120

- Unwinder

- Single shafted motor braked. Width 1600mm

- Note

- attenzione 24-07-25 macchina smontata Flexo-loop bags w/wo bottom gusset Flexo-loop bags with reinforcement turn-up w/wo bottom gusset Die cut handle bags Die cut handle bags with reinforcement turn-up Material that can be processed:LDPE,HDPE, and recycled extracts Max welding width: Up to 850 mm Sealing width (bag length): 250-800mm Draw length (bag width): 250-800 mm Handle width: 30mm loop thickness:180-230 micron Driving system: PLC controlled Operator interface terminal Print registration control Servo motor driven input nip rollers 2 sealing bars, 1 for side and 1 for bottom seal

| Machine Code | FI521 |

| Manufacturer | DE BERNARDI |

| Modello | DB100N SH |

| Year | 2007 |

| Type of delivery | Conveyor table |

| Type of handle | Multiple (patch and softloop) |

| Type of sealing/bags | Side weld |

| Type of bags | Soft loop handles |

| Working width (mm) | 850 |

| Number of lanes | 1 |

| Bag length | 250-800 |

| Bag width | 250-800 |

| Cycle / min | 100-120 |

| Unwinder | Single shafted motor braked. Width 1600mm |

| Note | attenzione 24-07-25 macchina smontata Flexo-loop bags w/wo bottom gusset Flexo-loop bags with reinforcement turn-up w/wo bottom gusset Die cut handle bags Die cut handle bags with reinforcement turn-up Material that can be processed:LDPE,HDPE, and recycled extracts Max welding width: Up to 850 mm Sealing width (bag length): 250-800mm Draw length (bag width): 250-800 mm Handle width: 30mm loop thickness:180-230 micron Driving system: PLC controlled Operator interface terminal Print registration control Servo motor driven input nip rollers 2 sealing bars, 1 for side and 1 for bottom seal |

ERS 1800

-

Machine Code: FI539

-

Year: 2008

-

Working width (mm): 1800

MOBERT ROLLER 110 2M-AUT/300

-

Machine Code: FI538

-

Year: 2020

-

Working width (mm): 1100

MOBERT NASTROSAC 6M

-

Machine Code: FI529

-

Year: 2002

-

Working width (mm): 1100

ELBA SA9011HS

-

Machine Code: FI592

-

Year: 1997

-

Bag width: 200 - 1000

MOBERT NASTROSAC TN 13 NS9

-

Machine Code: FI579

-

Year: 2010

-

Working width (mm): 1100