A Vacuum metallizer is used to coat a layer of aluminium (or other metals) onto a web, typically plastic film or paper.

Ask more informations

- Machine Code

- ME080

- Manufacturer

- GENERAL VACUUM EQUIPMENT

- Modello

- EHF 2250-2250

- Year

- 1998

- Working width (mm)

- 2250

- Materials

- BOPP 15-80my ; PET 09-50my; CPP 20-40my; LDPE 25-50my ; Nylon 12-50my ; UPVC 20-80my

- Speed

- 72-720m/min line speed

- Max diameter reel unwinder

- 1000mm

- Max diameter reel rewinder

- 1000mm

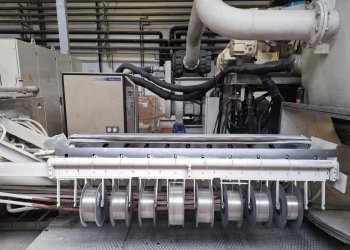

- Evapouration Boots

- 24pc . Evaporation boats size : 150*30*9mm

- Pumping system

- Pumping configuration ( 50HZ/60HZ )

- Polycold

- yes , 2 PFC 1100 HC

- Note

- Max web width 2250mm / Min web width 1450mm Max roll diam 1250mm ( modification made to increase from 1000mm ) .Core internal diam 152mm Evaporation zone operating pressure 5x10-4 mbar ; Winding zone operating pressure : 2x 10-2 mbar Evaporation zone : - 2x 50,000 l/s NHS-35 Varian diffusion pump ; - 2 x 2000/2400 m3/h Aerzen (GLA 13.F7 HV ) booster pump ; - 2 x300/505 m3/h Kinney (505LP) rotary piston pump -2x 200,000 l/s Polycold PFC 1100 HC cryogenic pump (modification made to put both units in evaporation zone to increase efficiency ) Evaporation source type : resistance heated intermetalic (boats) Winding zone : - 2 x 12700/15200 m3/h Holmes Dresser booster pump -2x3000/3500 m3/h Holmes Dresser booster pump -2x 300/505 m3/h Kinney (505LP) rotary piston pump Winding Mechanism : Line speed : 72-720m/min Unwind tension : 320N Rewind tension : 320N (min tension 20-25N ) Alum wire : 1.6mm -2mm 98.2% purity ( variable gap instead of fixed gap ). Aluminum wire spool size 300-350mm Metalizing data : Max deposition rate : 1.8 ohms at 720m/min Deposition uniformity : depend upon material and running speed Thicnkess range of deposition : 100-200 angstrom Evaporator life : 15 hours average Spare parts available

| Machine Code | ME080 |

| Manufacturer | GENERAL VACUUM EQUIPMENT |

| Modello | EHF 2250-2250 |

| Year | 1998 |

| Working width (mm) | 2250 |

| Materials | BOPP 15-80my ; PET 09-50my; CPP 20-40my; LDPE 25-50my ; Nylon 12-50my ; UPVC 20-80my |

| Speed | 72-720m/min line speed |

| Max diameter reel unwinder | 1000mm |

| Max diameter reel rewinder | 1000mm |

| Evapouration Boots | 24pc . Evaporation boats size : 150*30*9mm |

| Pumping system | Pumping configuration ( 50HZ/60HZ ) |

| Polycold | yes , 2 PFC 1100 HC |

| Note | Max web width 2250mm / Min web width 1450mm Max roll diam 1250mm ( modification made to increase from 1000mm ) .Core internal diam 152mm Evaporation zone operating pressure 5x10-4 mbar ; Winding zone operating pressure : 2x 10-2 mbar Evaporation zone : - 2x 50,000 l/s NHS-35 Varian diffusion pump ; - 2 x 2000/2400 m3/h Aerzen (GLA 13.F7 HV ) booster pump ; - 2 x300/505 m3/h Kinney (505LP) rotary piston pump -2x 200,000 l/s Polycold PFC 1100 HC cryogenic pump (modification made to put both units in evaporation zone to increase efficiency ) Evaporation source type : resistance heated intermetalic (boats) Winding zone : - 2 x 12700/15200 m3/h Holmes Dresser booster pump -2x3000/3500 m3/h Holmes Dresser booster pump -2x 300/505 m3/h Kinney (505LP) rotary piston pump Winding Mechanism : Line speed : 72-720m/min Unwind tension : 320N Rewind tension : 320N (min tension 20-25N ) Alum wire : 1.6mm -2mm 98.2% purity ( variable gap instead of fixed gap ). Aluminum wire spool size 300-350mm Metalizing data : Max deposition rate : 1.8 ohms at 720m/min Deposition uniformity : depend upon material and running speed Thicnkess range of deposition : 100-200 angstrom Evaporator life : 15 hours average Spare parts available |

GENERAL VACUUM EQUIPMENT EHF 1650

-

Machine Code: ME103

-

Year: 1994

-

Working width (mm): 1650

GALILEO MEGA 2010 / B

-

Machine Code: ME062

-

Year: 2005

-

Working width (mm): 2020

BOBST K5000

-

Machine Code: ME101

-

Year: 2014

-

Working width (mm): 2450

GENERAL VACUUM EQUIPMENT K2450

-

Machine Code: ME086

-

Year: 2003

-

Working width (mm): 2450

GALILEO V316/P

-

Machine Code: ME097

-

Year: 2000

-

Working width (mm): 1650

GALILEO MEGA 2410

-

Machine Code: ME077

-

Year: 2002

-

Working width (mm): 2400