** SOLD **

Coatings used in packaging industry are various. Cold and hot seal coating are common. Also, cold and hot seal coatings are commonly used, as well as hot melt and wax coatings. Silicon, Pvdc coating, ant mist and many others are employed. Materials which can be coated with a certain machine depends highly on the type of coating unit(s) available, on machine's construction and equipment.

Ask more informations

about a similar one

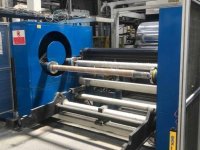

- Machine Code

- LA302

- Manufacturer

- GHEZZI & ANNONI

- Modello

- HOTMELT

- Year

- 2002

- Application

- Coating

- Type of lamination/coating

- Hot melt

- Working width (mm)

- 1650

- Materials

- BOPP, Celofan, Masking tape, Polythene Strapping, Reinforced

- Speed

- Mechanical speed : 350 m/min Machine running speed: 300 m/min (18g/m2 adhesive)

- First unwinder type

- Jumbo

- Max diameter reel unwinder

- 1000

- Rewinder type

- Jumbo

- Max diameter reel rewinder

- 1000

- Coating unit

- 1 by Mayer bar

- Second Coating unitr

- 2 extruders

- Drying

- Thermic oil - Electric for die

- Note

- Winder was replaced in 2007 with a newer one scrapless. Automatic duplex Unwinder auto splice Release Unit completed with TRESU closed Dr Blade Adhesive coating die ( Simplas ) Adhesive preparation Unit Automatic duplex Rewinder auto splice LEL System + LEL Alert Hotmelt Adhesive filter : mahle system Edge guide unit : 1-before coating die 1-before rewinder Hotmelt adhesive: 12g/m2 – 120 g/m2 Temperature: Between 100-200°C Adhesive : Mixed with SIS rubber and SBS Viscosity: Between 10,000 – 100,000 CPS Release Drying Tunnels; 1 Oven with a total heating power 350.000Kcal/h Total Air flow: 18,000m3/h Max working temperature: 120°C Entrance temperature: 20°C Air absorption capacity: 14,000Nm3/h approx.

| Machine Code | LA302 |

| Manufacturer | GHEZZI & ANNONI |

| Modello | HOTMELT |

| Year | 2002 |

| Application | Coating |

| Type of lamination/coating | Hot melt |

| Working width (mm) | 1650 |

| Materials | BOPP, Celofan, Masking tape, Polythene Strapping, Reinforced |

| Speed | Mechanical speed : 350 m/min Machine running speed: 300 m/min (18g/m2 adhesive) |

| First unwinder type | Jumbo |

| Max diameter reel unwinder | 1000 |

| Rewinder type | Jumbo |

| Max diameter reel rewinder | 1000 |

| Coating unit | 1 by Mayer bar |

| Second Coating unitr | 2 extruders |

| Drying | Thermic oil - Electric for die |

| Note | Winder was replaced in 2007 with a newer one scrapless. Automatic duplex Unwinder auto splice Release Unit completed with TRESU closed Dr Blade Adhesive coating die ( Simplas ) Adhesive preparation Unit Automatic duplex Rewinder auto splice LEL System + LEL Alert Hotmelt Adhesive filter : mahle system Edge guide unit : 1-before coating die 1-before rewinder Hotmelt adhesive: 12g/m2 – 120 g/m2 Temperature: Between 100-200°C Adhesive : Mixed with SIS rubber and SBS Viscosity: Between 10,000 – 100,000 CPS Release Drying Tunnels; 1 Oven with a total heating power 350.000Kcal/h Total Air flow: 18,000m3/h Max working temperature: 120°C Entrance temperature: 20°C Air absorption capacity: 14,000Nm3/h approx. |

UTECO CORAL

-

Machine Code: LA132

-

Year: 2006

-

Working width (mm): 800

NORDMECCANICA Simplex sl

-

Machine Code: LA494

-

Year: 2005

-

Working width (mm): 1300

Bubani Adhesive tape solvent base

-

Machine Code: LA312

-

Year: 1990

-

Working width (mm): 1350

SIDECO

-

Machine Code: LA159

-

Year: 1999

-

Working width (mm): 1650

ISOTEX

-

Machine Code: LA472

-

Year: 2014

-

Working width (mm): 1700

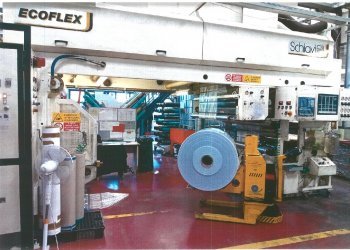

SCHIAVI ECOFLEX

-

Machine Code: LA378

-

Year: 2000

-

Working width (mm): 1420