** SOLD **

Coatings used in packaging industry are various. Cold and hot seal coating are common. Also, cold and hot seal coatings are commonly used, as well as hot melt and wax coatings. Silicon, Pvdc coating, ant mist and many others are employed. Materials which can be coated with a certain machine depends highly on the type of coating unit(s) available, on machine's construction and equipment.

Ask more informations

about a similar one

- Machine Code

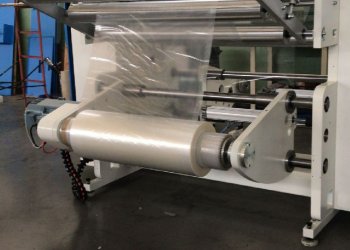

- LA297

- Manufacturer

- SOMA

- Modello

- LAMIFLEX

- Year

- 2010

- Application

- Duplex lamination

- Type of lamination/coating

- SOLVENTLESS

- Working width (mm)

- 1310

- Materials

- Materials to be processed: Primary adhesive application materials: BOPP 0.012 - 0.08 mm ; PET 0.01 - 0.06 mm ;PE, LDPE 0.04 - 0.2 mm ;OPA 0.012 - 0.06 mm ;CAST PP 0.06 - 0.15 mm ;CAST PA 0.05 - 0.08 mm ; Alu foil 0.012 - 0.04 mm ; Paper 30-150 g/m2 ;Laminate up to 100 g/m2 . Secondary materials are laminated: BOPP 0.012 - 0.08 mm; PET 0,008 - 0,03 mm; PE, LDPE 0.02 - 0.2 mm ;OPA 0.012 - 0.06 ;CAST PP 0.02 - 0.15 mm ;CAST PA 0.02 - 0.08 mm ;Al foil 0,008 -0,04 mm ;Paper 30 - 150 g/m2

- Speed

- 400 m/min . Working speed of lamination 100 - 250 m/min

- Max diameter reel unwinder

- 1000

- Max diameter reel rewinder

- 1000

- pumping mixing unit

- Mixer two components Vea Matrix M5 year 2009

- Note

- Material width 300-1320 mm Unwinder able to work with 76 and 152 mm shafts,Reels weight 1000 kg Rewinder able to work with 76 and 152 mm shafts, weight 1000 kg Maximum material thickness on the unwinding 0.3 mm

| Machine Code | LA297 |

| Manufacturer | SOMA |

| Modello | LAMIFLEX |

| Year | 2010 |

| Application | Duplex lamination |

| Type of lamination/coating | SOLVENTLESS |

| Working width (mm) | 1310 |

| Materials | Materials to be processed: Primary adhesive application materials: BOPP 0.012 - 0.08 mm ; PET 0.01 - 0.06 mm ;PE, LDPE 0.04 - 0.2 mm ;OPA 0.012 - 0.06 mm ;CAST PP 0.06 - 0.15 mm ;CAST PA 0.05 - 0.08 mm ; Alu foil 0.012 - 0.04 mm ; Paper 30-150 g/m2 ;Laminate up to 100 g/m2 . Secondary materials are laminated: BOPP 0.012 - 0.08 mm; PET 0,008 - 0,03 mm; PE, LDPE 0.02 - 0.2 mm ;OPA 0.012 - 0.06 ;CAST PP 0.02 - 0.15 mm ;CAST PA 0.02 - 0.08 mm ;Al foil 0,008 -0,04 mm ;Paper 30 - 150 g/m2 |

| Speed | 400 m/min . Working speed of lamination 100 - 250 m/min |

| Max diameter reel unwinder | 1000 |

| Max diameter reel rewinder | 1000 |

| pumping mixing unit | Mixer two components Vea Matrix M5 year 2009 |

| Note | Material width 300-1320 mm Unwinder able to work with 76 and 152 mm shafts,Reels weight 1000 kg Rewinder able to work with 76 and 152 mm shafts, weight 1000 kg Maximum material thickness on the unwinding 0.3 mm |

GENERAL CONVERTING MACHINES Olympia 1300

-

Machine Code: LA448

-

Year: 2019

-

Working width (mm): 1300

POLYTYPE POLYTYPE 522

-

Machine Code: LA348

-

Year: 1982

-

Working width (mm): 1040

ITALFLEX 2000-80

-

Machine Code: LA391

-

Year: 2001

-

Working width (mm): 900

ROTOMEC duplex

-

Machine Code: LA426

-

Year: 1980

-

Working width (mm): 800

CML MIRACH

-

Machine Code: LA453

-

Year: 2004

-

Working width (mm): 1300

BIELLONI Julia II

-

Machine Code: LA461

-

Year: 1998

-

Working width (mm): 1400