Coatings used in packaging industry are various. Cold and hot seal coating are common. Also, cold and hot seal coatings are commonly used, as well as hot melt and wax coatings. Silicon, Pvdc coating, ant mist and many others are employed. Materials which can be coated with a certain machine depends highly on the type of coating unit(s) available, on machine's construction and equipment.

Ask more informations

- Machine Code

- LA356

- Manufacturer

- MB

- Modello

- HOT MELT, WAX COATER LAMINATOR

- Year

- 2002

- Application

- Lamination + coating

- Type of lamination/coating

- COMBI / INTECHANGEABLE TROLLEY

- Working width (mm)

- 1700

- Materials

- Paper and board, Film and Alu foil ( secondary unwi)

- Speed

- 400 mpm

- First unwinder type

- Single position shaftless double brake

- Max diameter reel unwinder

- 1600

- Secondary unwinder type

- Single position shaftles

- Max diameter reel unwinder

- 1200

- Rewinder type

- Surface driven shaftless

- Max diameter reel rewinder

- 1900

- Coating unit

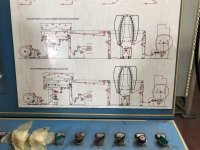

- Trolley design, available trolleys: - Semi flexo - hot melt/wax with Wax - Hot melt trolley and Semi flexo trolley 3 meter tunnel with one blowing and one exhaus fan and one gas burner for lamination unit with semiflexo trolley

- Second Coating unitr

- - Type direct gravure - 2x drying tunnels 4 m length ( tot 8 m) with independent ventilation - 2 x gas burners, 2 x in blowers, 1 x suction blower. - Automatic recirculation with Nira LEL control - Coating rollers 30,70,80,280 lines/cm

- pumping mixing unit

- Premelting unit Nordson for Wax coating

- Coating rollers

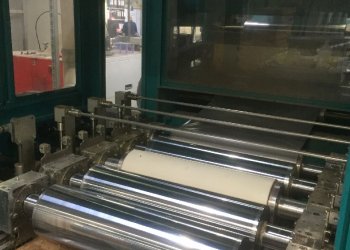

- 6 anilox rollers and 40 sleeves for gravure coating nip roll

- Note

- Possible operation 1) Wax Coating laminating Paper - Alu foil or paper film and primer in line 2) Wax paper coating one side or doiuble side 3) Hot melt coating 4) Water based lamination wet bond paper -Alu foil with semiflexo trolley and primer in line 5) Water based lamination + costing or lacquering

| Machine Code | LA356 |

| Manufacturer | MB |

| Modello | HOT MELT, WAX COATER LAMINATOR |

| Year | 2002 |

| Application | Lamination + coating |

| Type of lamination/coating | COMBI / INTECHANGEABLE TROLLEY |

| Working width (mm) | 1700 |

| Materials | Paper and board, Film and Alu foil ( secondary unwi) |

| Speed | 400 mpm |

| First unwinder type | Single position shaftless double brake |

| Max diameter reel unwinder | 1600 |

| Secondary unwinder type | Single position shaftles |

| Max diameter reel unwinder | 1200 |

| Rewinder type | Surface driven shaftless |

| Max diameter reel rewinder | 1900 |

| Coating unit | Trolley design, available trolleys: - Semi flexo - hot melt/wax with Wax - Hot melt trolley and Semi flexo trolley 3 meter tunnel with one blowing and one exhaus fan and one gas burner for lamination unit with semiflexo trolley |

| Second Coating unitr | - Type direct gravure - 2x drying tunnels 4 m length ( tot 8 m) with independent ventilation - 2 x gas burners, 2 x in blowers, 1 x suction blower. - Automatic recirculation with Nira LEL control - Coating rollers 30,70,80,280 lines/cm |

| pumping mixing unit | Premelting unit Nordson for Wax coating |

| Coating rollers | 6 anilox rollers and 40 sleeves for gravure coating nip roll |

| Note | Possible operation 1) Wax Coating laminating Paper - Alu foil or paper film and primer in line 2) Wax paper coating one side or doiuble side 3) Hot melt coating 4) Water based lamination wet bond paper -Alu foil with semiflexo trolley and primer in line 5) Water based lamination + costing or lacquering |

GENERAL CONVERTING MACHINES Olympia 1300

-

Machine Code: LA448

-

Year: 2019

-

Working width (mm): 1300

NORDMECCANICA Simplex SL

-

Machine Code: LA514

-

Year: 1997

-

Working width (mm): 1300

NORDMECCANICA TRIPLEX COMBI

-

Machine Code: LA388

-

Year: 1998

-

Working width (mm): 1400

POLYTYPE TRIPLEX POLYNORM

-

Machine Code: LA331

-

Year: 1984

-

Working width (mm): 1270

Coatema

-

Machine Code: LA469

-

Year: 2017

-

Working width (mm): 700

NORDMECCANICA SIMPLEX COMBI

-

Machine Code: LA495

-

Year: 1998

-

Working width (mm): 1315