Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

- Machine Code

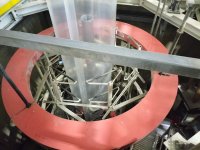

- EX791

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- Optimex

- Year

- 2011

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE, LLDPE

- Film Width

- 1800

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 60

- Description 1

- Gravimetric dosing system Doteco 6 Components

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 90

- Description 2

- Gravimetric dosing system Doteco 4Components

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 60

- Description 3

- Gravimetric dosing system Doteco 6 Components

- Head description

- Dual flow air ring, IBC,

- Die diam (mm)

- 300

- Thickness controll system

- Yes K design, Opifil plus

- Panel for gussets

- YES

- Take off unit

- Oscillating

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 800

| Machine Code | EX791 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | Optimex |

| Year | 2011 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE, LLDPE |

| Film Width | 1800 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 60 |

| Description 1 | Gravimetric dosing system Doteco 6 Components |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 90 |

| Description 2 | Gravimetric dosing system Doteco 4Components |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 60 |

| Description 3 | Gravimetric dosing system Doteco 6 Components |

| Head description | Dual flow air ring, IBC, |

| Die diam (mm) | 300 |

| Thickness controll system | Yes K design, Opifil plus |

| Panel for gussets | YES |

| Take off unit | Oscillating |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 800 |

TECOM EKN90-30D

-

Machine Code: EX790

-

Year: 1993

-

Film Width: 1800

KIEFEL KIRION 10

-

Machine Code: EX809

-

Year: 2002

-

Film Width: 1600

KUNG HSING KS-MH50+55/380V- 50HZ

-

Machine Code: EX768

-

Year: 2018

-

Film Width: 1200

DOLCI - ZOCCHI

-

Machine Code: EX813

-

Year: 2006

-

Film Width: 1600