** SOLD **

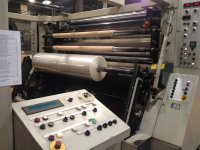

Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

about a similar one

- Machine Code

- CA147

- Manufacturer

- REIFENHAUSER

- Year

- 1991

- Number of layers

- 3

- Material

- CPP, STRETCH FILM, Barrier fim

- Film width (mm)

- 2100

- Output (Kg/h)

- 550 kg/h

- Screw diam 1

- 120

- Screw diam 2

- 90

- Screw diam 3

- 70

- Chill roll unit

- Edge pinning Rolltex

- Thickness controll system

- Automatic thickness control system

- Corona treatment

- Yes - Make AFS with silicon roller

- Rewinder max reel diameter (mm)

- 2500

- Note

- Thickness: 20-150 micron Inline edge trim recovery Including accessories: scrap recycling unit FS090.1-1-90-3.5; chiller; 320 kW/hour

| Machine Code | CA147 |

| Manufacturer | REIFENHAUSER |

| Year | 1991 |

| Number of layers | 3 |

| Material | CPP, STRETCH FILM, Barrier fim |

| Film width (mm) | 2100 |

| Output (Kg/h) | 550 kg/h |

| Screw diam 1 | 120 |

| Screw diam 2 | 90 |

| Screw diam 3 | 70 |

| Chill roll unit | Edge pinning Rolltex |

| Thickness controll system | Automatic thickness control system |

| Corona treatment | Yes - Make AFS with silicon roller |

| Rewinder max reel diameter (mm) | 2500 |

| Note | Thickness: 20-150 micron Inline edge trim recovery Including accessories: scrap recycling unit FS090.1-1-90-3.5; chiller; 320 kW/hour |

TECHNO COATING ENGINEERING

-

Machine Code: CA168

-

Year: 1999

-

Film width (mm): 3000

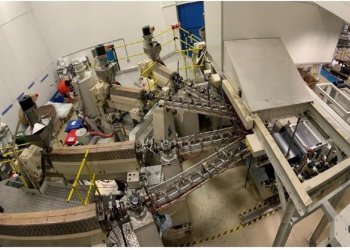

COLINES AllRollEx

-

Machine Code: CA202

-

Year: 2016

-

Film width (mm): 1500

COLINES ALL ROLL EX 1500

-

Machine Code: CA215

-

Year: 2017

-

Film width (mm): 1500