** SOLD **

Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

about a similar one

- Machine Code

- CA101

- Manufacturer

- REIFENHAUSER

- Year

- 1993

- Number of layers

- 3

- Film structure

- ABC

- Material

- CPP

- Film width (mm)

- 3100

- Output (Kg/h)

- 1000

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 90mm

- Description 1

- Bimetallic, Gravimetric dosing unit, 2 components;

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 180mm

- Description 2

- Gravimetric dosing unit, 3 components; Extruder on side for reefed of edge-trim

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 90mm

- Description 3

- L/D30 ; Gravimetric dosing unit, 2 components;

- Head description

- Make Reifenhauser; Feedblock;

- Chill roll unit

- 2 chill roll,1st 1000mm diam.

- Thickness controll system

- Automatic thickness control Eberline Kripton 85 - radio active source replaces 2008

- Corona treatment

- 2 AFS (front and back)

- Rewinder max reel diameter (mm)

- 800mm

- Rewinder description

- Turret , contact and gap type.Automatic, with 4 shafts on rewinder; Automatic brandable arms for completly automatic reels unloading and new cores loading. Automatic system to upload finished reels, packaging and for inserting new cores.

- Note

- In Line slitting unit; 2 x In line recovery trims system with exact trimming and supplementary extruder. Additional equipment : Kelvi plast Termo regulation unit. Machine currently dismantled

| Machine Code | CA101 |

| Manufacturer | REIFENHAUSER |

| Year | 1993 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | CPP |

| Film width (mm) | 3100 |

| Output (Kg/h) | 1000 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 90mm |

| Description 1 | Bimetallic, Gravimetric dosing unit, 2 components; |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 180mm |

| Description 2 | Gravimetric dosing unit, 3 components; Extruder on side for reefed of edge-trim |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 90mm |

| Description 3 | L/D30 ; Gravimetric dosing unit, 2 components; |

| Head description | Make Reifenhauser; Feedblock; |

| Chill roll unit | 2 chill roll,1st 1000mm diam. |

| Thickness controll system | Automatic thickness control Eberline Kripton 85 - radio active source replaces 2008 |

| Corona treatment | 2 AFS (front and back) |

| Rewinder max reel diameter (mm) | 800mm |

| Rewinder description | Turret , contact and gap type.Automatic, with 4 shafts on rewinder; Automatic brandable arms for completly automatic reels unloading and new cores loading. Automatic system to upload finished reels, packaging and for inserting new cores. |

| Note | In Line slitting unit; 2 x In line recovery trims system with exact trimming and supplementary extruder. Additional equipment : Kelvi plast Termo regulation unit. Machine currently dismantled |

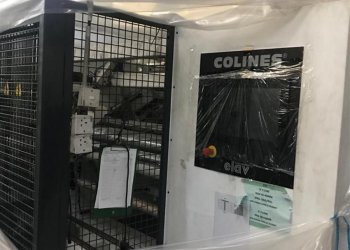

COLINES

-

Machine Code: CA261

-

Year: 2017

-

Film width (mm): 1500

ADTECH PROVERA HR 1000/3

-

Machine Code: CA206

-

Year: 2005

-

Film width (mm): 1000

TECHNO COATING ENGINEERING 2000/5 PLUS 4E

-

Machine Code: CA125

-

Year: 2004

-

Film width (mm): 2000

COLINES ALL ROLL EX 1500

-

Machine Code: CA215

-

Year: 2017

-

Film width (mm): 1500

PRIMPLAST

-

Machine Code: CA152

-

Year: 1999

-

Film width (mm): 2000