** SOLD **

A duplex laminator will joins 2 layer of web, a triplex lamination machine will join 3 layers together in 1 pass. Coating machines are used to apply a layer of coated material onto a web (support).

Ask more informations

about a similar one

- Machine Code

- LA302

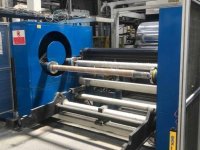

- Manufacturer

- GHEZZI & ANNONI

- Modello

- HOTMELT

- Year

- 2002

- Application

- Coating

- Type of lamination/coating

- Hot melt

- Working width (mm)

- 1650

- Materials

- BOPP, Celofan, Masking tape, Polythene Strapping, Reinforced

- Speed

- Mechanical speed : 350 m/min Machine running speed: 300 m/min (18g/m2 adhesive)

- First unwinder type

- Jumbo

- Max diameter reel unwinder

- 1000

- Rewinder type

- Jumbo

- Max diameter reel rewinder

- 1000

- Coating unit

- 1 by Mayer bar

- Second Coating unitr

- 2 extruders

- Drying

- Thermic oil - Electric for die

- Note

- Winder was replaced in 2007 with a newer one scrapless. Automatic duplex Unwinder auto splice Release Unit completed with TRESU closed Dr Blade Adhesive coating die ( Simplas ) Adhesive preparation Unit Automatic duplex Rewinder auto splice LEL System + LEL Alert Hotmelt Adhesive filter : mahle system Edge guide unit : 1-before coating die 1-before rewinder Hotmelt adhesive: 12g/m2 – 120 g/m2 Temperature: Between 100-200°C Adhesive : Mixed with SIS rubber and SBS Viscosity: Between 10,000 – 100,000 CPS Release Drying Tunnels; 1 Oven with a total heating power 350.000Kcal/h Total Air flow: 18,000m3/h Max working temperature: 120°C Entrance temperature: 20°C Air absorption capacity: 14,000Nm3/h approx.

| Machine Code | LA302 |

| Manufacturer | GHEZZI & ANNONI |

| Modello | HOTMELT |

| Year | 2002 |

| Application | Coating |

| Type of lamination/coating | Hot melt |

| Working width (mm) | 1650 |

| Materials | BOPP, Celofan, Masking tape, Polythene Strapping, Reinforced |

| Speed | Mechanical speed : 350 m/min Machine running speed: 300 m/min (18g/m2 adhesive) |

| First unwinder type | Jumbo |

| Max diameter reel unwinder | 1000 |

| Rewinder type | Jumbo |

| Max diameter reel rewinder | 1000 |

| Coating unit | 1 by Mayer bar |

| Second Coating unitr | 2 extruders |

| Drying | Thermic oil - Electric for die |

| Note | Winder was replaced in 2007 with a newer one scrapless. Automatic duplex Unwinder auto splice Release Unit completed with TRESU closed Dr Blade Adhesive coating die ( Simplas ) Adhesive preparation Unit Automatic duplex Rewinder auto splice LEL System + LEL Alert Hotmelt Adhesive filter : mahle system Edge guide unit : 1-before coating die 1-before rewinder Hotmelt adhesive: 12g/m2 – 120 g/m2 Temperature: Between 100-200°C Adhesive : Mixed with SIS rubber and SBS Viscosity: Between 10,000 – 100,000 CPS Release Drying Tunnels; 1 Oven with a total heating power 350.000Kcal/h Total Air flow: 18,000m3/h Max working temperature: 120°C Entrance temperature: 20°C Air absorption capacity: 14,000Nm3/h approx. |

NORDMECCANICA SIMPLEX COMBI

-

Machine Code: LA495

-

Year: 1998

-

Working width (mm): 1315

KBA FLEXOTECNICA

-

Machine Code: LA492

-

Year: 2020

-

Working width (mm): 1300

TECMO Elflex 1100 R12

-

Machine Code: LA486

-

Year: 1970

-

Working width (mm): 1050

WINDMÖLLER & HÖLSCHER

-

Machine Code: LA257

-

Year: 1994

-

Working width (mm): 850

TECMO Elflex 1400 VA 7

-

Machine Code: LA487

-

Year: 1970

-

Working width (mm): 1330

REMAK MIZAR Solventless

-

Machine Code: LA435

-

Year: 2017

-

Working width (mm): 1600