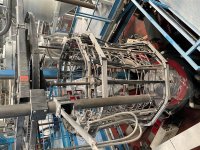

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

- Machine Code

- EX744

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- VAREX

- Year

- 2002

- Number of layers

- 5

- Overhaul/renovation

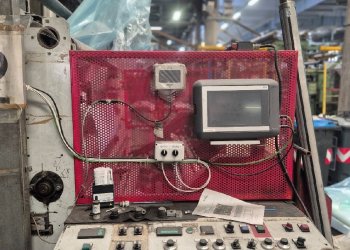

- HMI, supervision and some inverters upgraded in 2019

- Film structure

- ABCDE

- Material

- Barrier and lamination film, LDPE films

- Film Width

- 2100

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 70mm

- Description 1

- motor 89Kw, gravimetric doser 5 comp

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 50mm

- Description 2

- motor 29Kw gravimetric doser 1 comp

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 60mm

- Description 3

- motor 89Kw gravimetric doser 3 comp

- Extruder 4 Layer ref:

- D

- Screw diam 4

- 50mm

- Description 4

- motor 29Kw gravimetric doser 1 comp

- Extruder 5 Layer ref:

- E

- Screw diam 5

- 70mm

- Description 5

- motor 89Kw gravimetric doser 5 comp

- Head description

- IBC, OPTIFIL P2 automatic thickness profile control, auto width control via 3 ultrasonic sensors mounted on bubble cage

- Die diam (mm)

- 500mm, gap 1.25mm and 2.25mm

- Thickness controll system

- YES , 2 thickness gauges a. gauge beta control b. Electronic system model HISCAN, year 2009 for measuring thickness of overall film and of EVOH layer. Automatic thickness control OPTIFIL P"

- Bubble cage

- Motorized position, rotating

- Take off unit

- rotating

- Corona treatment

- Double corona treatment

- Web guide

- Yes

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1200mm

- Rewinder description

- . Surface or Gap winding. Reel unwinding and shaft extraction system. 3" and 6 " shafts

- Note

- Euro Chiller

| Machine Code | EX744 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | VAREX |

| Year | 2002 |

| Number of layers | 5 |

| Overhaul/renovation | HMI, supervision and some inverters upgraded in 2019 |

| Film structure | ABCDE |

| Material | Barrier and lamination film, LDPE films |

| Film Width | 2100 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 70mm |

| Description 1 | motor 89Kw, gravimetric doser 5 comp |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 50mm |

| Description 2 | motor 29Kw gravimetric doser 1 comp |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 60mm |

| Description 3 | motor 89Kw gravimetric doser 3 comp |

| Extruder 4 Layer ref: | D |

| Screw diam 4 | 50mm |

| Description 4 | motor 29Kw gravimetric doser 1 comp |

| Extruder 5 Layer ref: | E |

| Screw diam 5 | 70mm |

| Description 5 | motor 89Kw gravimetric doser 5 comp |

| Head description | IBC, OPTIFIL P2 automatic thickness profile control, auto width control via 3 ultrasonic sensors mounted on bubble cage |

| Die diam (mm) | 500mm, gap 1.25mm and 2.25mm |

| Thickness controll system | YES , 2 thickness gauges a. gauge beta control b. Electronic system model HISCAN, year 2009 for measuring thickness of overall film and of EVOH layer. Automatic thickness control OPTIFIL P" |

| Bubble cage | Motorized position, rotating |

| Take off unit | rotating |

| Corona treatment | Double corona treatment |

| Web guide | Yes |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1200mm |

| Rewinder description | . Surface or Gap winding. Reel unwinding and shaft extraction system. 3" and 6 " shafts |

| Note | Euro Chiller |

OMICRON COEX 3

-

Machine Code: EX605

-

Year: 1994

-

Film Width: 1600

KIEFEL KIRON ( COEX )

-

Machine Code: EX495

-

Year: 2010

-

Film Width: 2200

BIELLONI 100

-

Machine Code: EX787

-

Year: 2001

-

Film Width: 1800

WINDMÖLLER & HÖLSCHER

-

Machine Code: EX695

-

Year: 1989

-

Film Width: 1475