** SOLD **

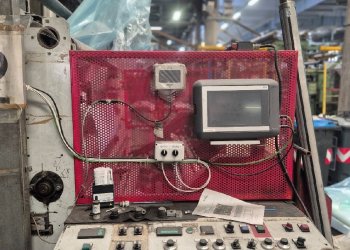

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

about a similar one

- Machine Code

- EX602

- Manufacturer

- BATTENFELD

- Year

- 1995

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE, LLDPE, EVA

- Film Width

- 3000

- Output (Kg/h)

- 750 kg/h

- Screw diam 1

- 80mm

- Screw diam 2

- 120mm

- Screw diam 3

- 80mm

- Head description

- Rotary

- Die diam (mm)

- 750

- Thickness controll system

- PLASTCONTROL

- Take off unit

- Fixed

- Corona treatment

- SHERMAN

- Rewinder Type

- Double back to back

| Machine Code | EX602 |

| Manufacturer | BATTENFELD |

| Year | 1995 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE, LLDPE, EVA |

| Film Width | 3000 |

| Output (Kg/h) | 750 kg/h |

| Screw diam 1 | 80mm |

| Screw diam 2 | 120mm |

| Screw diam 3 | 80mm |

| Head description | Rotary |

| Die diam (mm) | 750 |

| Thickness controll system | PLASTCONTROL |

| Take off unit | Fixed |

| Corona treatment | SHERMAN |

| Rewinder Type | Double back to back |

BATTENFELD

-

Machine Code: EX512

-

Year: 2003

-

Film Width: 2200

BIELLONI 100

-

Machine Code: EX787

-

Year: 2001

-

Film Width: 1800

KUNG HSING KS-AE50 / VOLTAGE 380V-50HZ

-

Machine Code: EX767

-

Year: 2015

-

Film Width: 700