** SOLD **

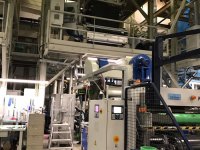

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

about a similar one

- Machine Code

- EX583

- Manufacturer

- KIEFEL

- Modello

- KIRION

- Year

- 2011

- Number of layers

- 3

- Material

- LDPE ,HDPE ,Bio

- Film Width

- 1300

- Screw diam 1

- 70mm

- Description 1

- L/D 26:1, Motox-Drive Technology (Siemens), Gravimetric Batch Blending with 4 components

- Screw diam 2

- 80mm

- Description 2

- L/D 26:1, Motox-Drive Technology (Siemens), Gravimetric Batch Blending with 4 components

- Screw diam 3

- 70mm

- Description 3

- L/D 26:1, Motox-Drive Technology (Siemens), Gravimetric Batch Blending with 4 components

- Head description

- Gap 1,8mm

- Die diam (mm)

- 175

- Thickness controll system

- Automating thickness controll

- Take off unit

- Rotating

- Corona treatment

- Ferrarini & Benelli

- Rewinder Type

- Single winder

- Note

- Chiller

| Machine Code | EX583 |

| Manufacturer | KIEFEL |

| Modello | KIRION |

| Year | 2011 |

| Number of layers | 3 |

| Material | LDPE ,HDPE ,Bio |

| Film Width | 1300 |

| Screw diam 1 | 70mm |

| Description 1 | L/D 26:1, Motox-Drive Technology (Siemens), Gravimetric Batch Blending with 4 components |

| Screw diam 2 | 80mm |

| Description 2 | L/D 26:1, Motox-Drive Technology (Siemens), Gravimetric Batch Blending with 4 components |

| Screw diam 3 | 70mm |

| Description 3 | L/D 26:1, Motox-Drive Technology (Siemens), Gravimetric Batch Blending with 4 components |

| Head description | Gap 1,8mm |

| Die diam (mm) | 175 |

| Thickness controll system | Automating thickness controll |

| Take off unit | Rotating |

| Corona treatment | Ferrarini & Benelli |

| Rewinder Type | Single winder |

| Note | Chiller |

BIELLONI Coex 3

-

Machine Code: EX770

-

Year: 2000

-

Film Width: 2000

REIFENHAUSER RT371

-

Machine Code: EX714

-

Year: 1989

-

Film Width: 1300

KIEFEL KIRON ( COEX )

-

Machine Code: EX495

-

Year: 2010

-

Film Width: 2200

DOLCI fIL 700

-

Machine Code: EX689

-

Year: 1990

-

Film Width: 3200