Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

- Machine Code

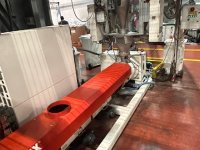

- EX806

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- Varex

- Year

- 2005

- Number of layers

- 1

- Overhaul/renovation

- Upgraded HMI/control panel

- Material

- LDPE, LLDPE, MDPE

- Film Width

- 1600

- Screw diam 1

- 90mm. L/D30

- Description 1

- Dosing system 3 components

- Head description

- IBC with automatic diameter control with 3 ultra sound sensors on basket, Automatic thickness control, Optifil P2

- Die diam (mm)

- 280

- Thickness controll system

- Automatic thickness control, Optifil P2

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1200mm

- Rewinder description

- Make Macchi, Model BO plus

- Note

- 2 colors in line print unit

| Machine Code | EX806 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | Varex |

| Year | 2005 |

| Number of layers | 1 |

| Overhaul/renovation | Upgraded HMI/control panel |

| Material | LDPE, LLDPE, MDPE |

| Film Width | 1600 |

| Screw diam 1 | 90mm. L/D30 |

| Description 1 | Dosing system 3 components |

| Head description | IBC with automatic diameter control with 3 ultra sound sensors on basket, Automatic thickness control, Optifil P2 |

| Die diam (mm) | 280 |

| Thickness controll system | Automatic thickness control, Optifil P2 |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1200mm |

| Rewinder description | Make Macchi, Model BO plus |

| Note | 2 colors in line print unit |

REIFENHAUSER RT371

-

Machine Code: EX714

-

Year: 1989

-

Film Width: 1300

BIELLONI 100

-

Machine Code: EX788

-

Year: 2000

-

Film Width: 1800