** SOLD **

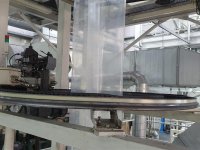

Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

about a similar one

- Machine Code

- EX638

- Manufacturer

- MACRO ENGINEERING

- Year

- 2002

- Number of layers

- 5

- Overhaul/renovation

- 2011

- Film structure

- A-B-C-D-E 30-200my

- Material

- LDPE, LLDPE, PA, EVOH, PP, coex tie resins

- Film Width

- 1500

- Output (Kg/h)

- 250

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 63

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 44

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 63

- Extruder 4 Layer ref:

- D

- Screw diam 4

- 44

- Extruder 5 Layer ref:

- E

- Screw diam 5

- 63

- Head description

- 5 layer with IBC

- Die diam (mm)

- 350

- Thickness controll system

- Yes x-rays SYSMETRIC

- Bubble cage

- Yes

- Take off unit

- Rotating

- Corona treatment

- Yes

- Web guide

- Yes E&L

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1000

- Rewinder description

- In line slitting

- Note

- Gravimetric system Plastcontrol brand. 2 components for 1,2,4,5, extruders and 1 for extruder 3. In 2011 the head and all screws were replaced, System Scada and Thorpe added by Macro, control panel and drivers replaced. Kundig gauge measuring system added instead of old Plastcontrol.

| Machine Code | EX638 |

| Manufacturer | MACRO ENGINEERING |

| Year | 2002 |

| Number of layers | 5 |

| Overhaul/renovation | 2011 |

| Film structure | A-B-C-D-E 30-200my |

| Material | LDPE, LLDPE, PA, EVOH, PP, coex tie resins |

| Film Width | 1500 |

| Output (Kg/h) | 250 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 63 |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 44 |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 63 |

| Extruder 4 Layer ref: | D |

| Screw diam 4 | 44 |

| Extruder 5 Layer ref: | E |

| Screw diam 5 | 63 |

| Head description | 5 layer with IBC |

| Die diam (mm) | 350 |

| Thickness controll system | Yes x-rays SYSMETRIC |

| Bubble cage | Yes |

| Take off unit | Rotating |

| Corona treatment | Yes |

| Web guide | Yes E&L |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1000 |

| Rewinder description | In line slitting |

| Note | Gravimetric system Plastcontrol brand. 2 components for 1,2,4,5, extruders and 1 for extruder 3. In 2011 the head and all screws were replaced, System Scada and Thorpe added by Macro, control panel and drivers replaced. Kundig gauge measuring system added instead of old Plastcontrol. |

WINDMÖLLER & HÖLSCHER OPTIMEX

-

Machine Code: EX763

-

Year: 2014

-

Film Width: 2200

WINDMÖLLER & HÖLSCHER VAREX

-

Machine Code: EX780

-

Year: 2003

-

Film Width: 2150

TECNOVA ES90B / 30D

-

Machine Code: EX789

-

Year: 2020

-

Film Width: 1800