** SOLD **

Raw material most commonly used are low density polyethylene (LDPE) and High density polyethylene (HDPE). These are often used in blends with other polymers and additives.

Ask more informations

about a similar one

- Machine Code

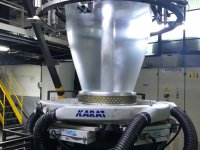

- EX621

- Manufacturer

- BANDERA

- Year

- 2005

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE, LLDPE

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 65

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 85

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 65

- Head description

- IBC

- Die diam (mm)

- 350 and 400 with 1.4 and 2.4 gaps

- Bubble cage

- Yes

- Note

- Electric boards Control panel of die/extruders/gravimetrics

| Machine Code | EX621 |

| Manufacturer | BANDERA |

| Year | 2005 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE, LLDPE |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 65 |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 85 |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 65 |

| Head description | IBC |

| Die diam (mm) | 350 and 400 with 1.4 and 2.4 gaps |

| Bubble cage | Yes |

| Note | Electric boards Control panel of die/extruders/gravimetrics |

WINDMÖLLER & HÖLSCHER

-

Machine Code: EX695

-

Year: 1989

-

Film Width: 1475

REIFENHAUSER

-

Machine Code: EX637

-

Year: 2002

-

Film Width: 1800

WINDMÖLLER & HÖLSCHER VAREX

-

Machine Code: EX780

-

Year: 2003

-

Film Width: 2150