** SOLD **

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

about a similar one

- Machine Code

- EX616

- Manufacturer

- BANDERA

- Modello

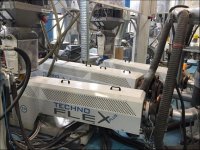

- TECHNOFLEX

- Year

- 2015

- Number of layers

- 3

- Film structure

- ABC

- Material

- STRETCH ,LLDPE, LDPE, EVA, mLLDPE

- Film Width

- 1700

- Output (Kg/h)

- Max production: Stretch hood with 280 mm die plate: 450 kg/h ;Shrink or lamination film with 400 mm die plate: 600 kg/h

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 60MM

- Description 1

- 30D ,3 gravimetric batch dosing units 4 components

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 100MM

- Description 2

- 30D ,3 gravimetric batch dosing units 4 components

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 60MM

- Description 3

- 30D ,3 gravimetric batch dosing units 4 components

- Head description

- IBC ,,Air Ring Karat 3 Com with high adjustment

- Die diam (mm)

- 280 and 400 mm

- Thickness controll system

- Automatic thickness control system Kundig

- Panel for gussets

- Gusseting

- Take off unit

- Rotating haul off with gusseting device

- Corona treatment

- Corona treatment Cason for both sides

- Web guide

- Web guide 1800 mm

- Rewinder description

- Double automatic rewinder TW 1800

- Note

- Line to produce stretch hood, lamination film and shrink film Manual screen changers Motorized calibration basket Automatic core loading system SAFE LOAD Antistatic bars Chiller ABF Tower Thickness 20-200 my

| Machine Code | EX616 |

| Manufacturer | BANDERA |

| Modello | TECHNOFLEX |

| Year | 2015 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | STRETCH ,LLDPE, LDPE, EVA, mLLDPE |

| Film Width | 1700 |

| Output (Kg/h) | Max production: Stretch hood with 280 mm die plate: 450 kg/h ;Shrink or lamination film with 400 mm die plate: 600 kg/h |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 60MM |

| Description 1 | 30D ,3 gravimetric batch dosing units 4 components |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 100MM |

| Description 2 | 30D ,3 gravimetric batch dosing units 4 components |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 60MM |

| Description 3 | 30D ,3 gravimetric batch dosing units 4 components |

| Head description | IBC ,,Air Ring Karat 3 Com with high adjustment |

| Die diam (mm) | 280 and 400 mm |

| Thickness controll system | Automatic thickness control system Kundig |

| Panel for gussets | Gusseting |

| Take off unit | Rotating haul off with gusseting device |

| Corona treatment | Corona treatment Cason for both sides |

| Web guide | Web guide 1800 mm |

| Rewinder description | Double automatic rewinder TW 1800 |

| Note | Line to produce stretch hood, lamination film and shrink film Manual screen changers Motorized calibration basket Automatic core loading system SAFE LOAD Antistatic bars Chiller ABF Tower Thickness 20-200 my |

WINDMÖLLER & HÖLSCHER VAREX

-

Machine Code: EX744

-

Year: 2002

-

Film Width: 2100

BIELLONI Coex 3

-

Machine Code: EX764

-

Year: 1999

-

Film Width: 1700

KUNG HSING KS-MH50+55/380V- 50HZ

-

Machine Code: EX768

-

Year: 2018

-

Film Width: 1200

BATTENFELD

-

Machine Code: EX512

-

Year: 2003

-

Film Width: 2200