- Código Máquina

- LAB234

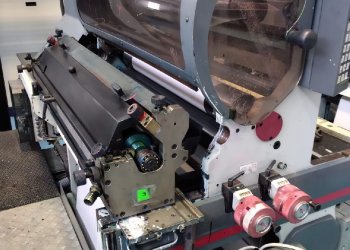

- Constructor

- OMET

- Modello

- Varyflex VF420 FP

- Año

- 2004

- Number of colors

- 9

- Web width (mm)

- 420

- Print width (mm)

- 405

- Print repeat range (mm)

- Printing repeat min 304,8 mm / max 838,2 mm.

- Drying

- Hot air drying system: possibility only unit no 6 and no 9

- Unwinder

- 1000MM

- Note

- Introduction + hot air – 60KW +120kW 400V 50Hz 3ph Compressed air – 6bar. 400l/min The standard unit was with 7 section, 2 additional sections were added to the unit, and now it is 9 sections. Old UV lamps have been replaced with E2C UV lamps. Material 12mkm film / 600 mkm cardboard Max speed 150 m/min Air pressure 6 bar Printing register adjustment 360 Maximum print width 405 mm Maximum die cutting width 405 mm Maximum die cutting repeat min 304,8 mm / max 609,6 mm Unwinder spindle diameter 76,2 mm Rewinder spindle diameter 2 shaft 76,2 mm Unwinder diameter 1000 mm Vacuum system, double side web cleaner 1psc One side corona treatment 1 psc UV curing system: single lamp UV GEW E2C system Hot air drying system: possibility only unit no 6 and no 9 Kit for reverse printing. Including enclosed chamber doctor blade and peristatic pump: Possibility unit no 8 Water cooling drums after each printing unit: chiller not included Possibility UV laminating: unit no 8 Motorized video camera EL scan Set of antistatic bars Web breake sensor 1 psc Servo driven mandrel for printing sleeves Printing preasure adjusment on 4 independent points Register adjustment is possible on every deck or at product Operator interface through touch screen panel Plate speed correction +- 2 % (slipping ) Inks pan with rubbel roll 12 psc Web turn bar Slitting unit Spare parts, accessories, technical documentation included l L/CM 60 DEGREES VOLUME CM3/M3 PSC 460 2,9 3 410 4 3 320 5 3 320 4 Twinflo reverse 1 psc 200 6,5 2 180 7,7 1 160 10 1 140 8,7 3

| Código Máquina | LAB234 |

| Constructor | OMET |

| Modello | Varyflex VF420 FP |

| Año | 2004 |

| Number of colors | 9 |

| Web width (mm) | 420 |

| Print width (mm) | 405 |

| Print repeat range (mm) | Printing repeat min 304,8 mm / max 838,2 mm. |

| Drying | Hot air drying system: possibility only unit no 6 and no 9 |

| Unwinder | 1000MM |

| Note | Introduction + hot air – 60KW +120kW 400V 50Hz 3ph Compressed air – 6bar. 400l/min The standard unit was with 7 section, 2 additional sections were added to the unit, and now it is 9 sections. Old UV lamps have been replaced with E2C UV lamps. Material 12mkm film / 600 mkm cardboard Max speed 150 m/min Air pressure 6 bar Printing register adjustment 360 Maximum print width 405 mm Maximum die cutting width 405 mm Maximum die cutting repeat min 304,8 mm / max 609,6 mm Unwinder spindle diameter 76,2 mm Rewinder spindle diameter 2 shaft 76,2 mm Unwinder diameter 1000 mm Vacuum system, double side web cleaner 1psc One side corona treatment 1 psc UV curing system: single lamp UV GEW E2C system Hot air drying system: possibility only unit no 6 and no 9 Kit for reverse printing. Including enclosed chamber doctor blade and peristatic pump: Possibility unit no 8 Water cooling drums after each printing unit: chiller not included Possibility UV laminating: unit no 8 Motorized video camera EL scan Set of antistatic bars Web breake sensor 1 psc Servo driven mandrel for printing sleeves Printing preasure adjusment on 4 independent points Register adjustment is possible on every deck or at product Operator interface through touch screen panel Plate speed correction +- 2 % (slipping ) Inks pan with rubbel roll 12 psc Web turn bar Slitting unit Spare parts, accessories, technical documentation included l L/CM 60 DEGREES VOLUME CM3/M3 PSC 460 2,9 3 410 4 3 320 5 3 320 4 Twinflo reverse 1 psc 200 6,5 2 180 7,7 1 160 10 1 140 8,7 3 |

LOMBARDI FLEXOLINE 330

-

Código Máquina: LAB241

-

Año: 2009

-

Web width (mm): 350

OMET Varyflex V1

-

Código Máquina: LAB270

-

Año: 2011

-

Web width (mm):

NILPETER FA2400

-

Código Máquina: LAB263

-

Año: 1999

-

Web width (mm):

MARK ANDY DG1-13

-

Código Máquina: LAB242

-

Año: 2009

-

Web width (mm): 330

GALLUS TCS 250

-

Código Máquina: LAB247

-

Año: 2006

-

Web width (mm): 250

OMET XFLEX X6 530

-

Código Máquina: LAB272

-

Año: 2019

-

Web width (mm): 550