** SOLD **

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

about a similar one

- Machine Code

- EX536

- Manufacturer

- GHIOLDI

- Year

- 2000

- Number of layers

- 3

- Material

- LDPE

- Film Width

- 1800

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 60

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 60

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 60

- Head description

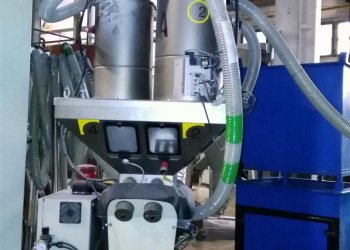

- IBC ; Gravimetric dosing Unit Doteco

- Die diam (mm)

- 320

- Thickness controll system

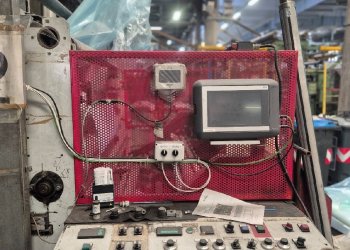

- Yes, Automatic Thickness Control PLASTCONTROL - model ACS PRO-CON

- Corona treatment

- Yes,Martignoni

- Web guide

- Yea, E+L

- Rewinder Type

- Undefined

- Rewinder max reel diameter

- 1800

- Note

- Complete Computer Supervision; Hydraulic screen Changer

| Machine Code | EX536 |

| Manufacturer | GHIOLDI |

| Year | 2000 |

| Number of layers | 3 |

| Material | LDPE |

| Film Width | 1800 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 60 |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 60 |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 60 |

| Head description | IBC ; Gravimetric dosing Unit Doteco |

| Die diam (mm) | 320 |

| Thickness controll system | Yes, Automatic Thickness Control PLASTCONTROL - model ACS PRO-CON |

| Corona treatment | Yes,Martignoni |

| Web guide | Yea, E+L |

| Rewinder Type | Undefined |

| Rewinder max reel diameter | 1800 |

| Note | Complete Computer Supervision; Hydraulic screen Changer |

MAM Z 2400 DW-SLW LD

-

Machine Code: EX766

-

Year: 2015

-

Film Width: 2400

OMICRON COEX 3

-

Machine Code: EX605

-

Year: 1994

-

Film Width: 1600

BANDERA Coex 7

-

Machine Code: EX781

-

Year: 2006

-

Film Width: 1800

BIELLONI 100

-

Machine Code: EX787

-

Year: 2001

-

Film Width: 1800