** SOLD **

Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

about a similar one

- Machine Code

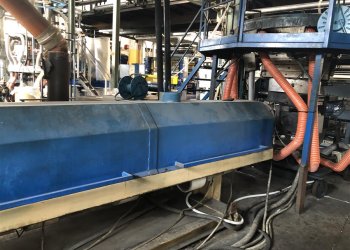

- EX751

- Manufacturer

- TECOM

- Year

- 2001

- Number of layers

- 1

- Material

- LDPE, MDPE

- Film Width

- 1700

- Output (Kg/h)

- 230

- Screw diam 1

- 65mm

- Description 1

- Gravimetric dosing unit Contrex with 2 components

- Head description

- Rotating die head

- Die diam (mm)

- 250

- Take off unit

- fixed

- Corona treatment

- Yes

- Rewinder Type

- Double back to back

| Machine Code | EX751 |

| Manufacturer | TECOM |

| Year | 2001 |

| Number of layers | 1 |

| Material | LDPE, MDPE |

| Film Width | 1700 |

| Output (Kg/h) | 230 |

| Screw diam 1 | 65mm |

| Description 1 | Gravimetric dosing unit Contrex with 2 components |

| Head description | Rotating die head |

| Die diam (mm) | 250 |

| Take off unit | fixed |

| Corona treatment | Yes |

| Rewinder Type | Double back to back |

BANDERA Coex 7

-

Machine Code: EX781

-

Year: 2006

-

Film Width: 1800

DOLCI fIL 700

-

Machine Code: EX689

-

Year: 1990

-

Film Width: 3200

BIELLONI Coex 3

-

Machine Code: EX764

-

Year: 1999

-

Film Width: 1700

KUNG HSING KS-MH50+55/380V- 50HZ

-

Machine Code: EX768

-

Year: 2018

-

Film Width: 1200