- Codice Macchina

- CA155

- Manufacturer

- SML

- Year

- 2015

- Numero di strati

- 5

- Struttura film

- ABCBD

- Materiali

- Stretch film LLDPE

- Larghezza film (mm)

- 2000

- Velocità (m/m)

- 600

- Output (Kg/h)

- 1200

- Rif strati estrusore 1:

- A

- Screw diam 1

- 60

- Description 1

- L/D 28,output 190 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer

- Rif strati estrusore 2:

- B

- Screw diam 2

- 90

- Description 2

- L/D 33,output 600 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer

- Rif strati estrusore 3:

- C

- Screw diam 3

- 90

- Description 3

- L/D 33,output 600 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer

- Rif strati estrusore 4:

- D

- Screw diam 4

- 60

- Description 4

- L/D 28,output 190 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer

- Descrizione testa

- 5 ply feedblock,Automatic die, Bivac vacuum box 2 chamber vacuum box, electrostatic edge pinning with 2 charging electrodes each with 3 fingers max 30 KV , pneumatic edge cooling

- Die width (mm)

- 2550

- Unità chill roll

- Chill roll unit model 1000/400; diam first chill roll 1000mm; diam second chill roll 400mm; contact lenght first chill roll 240 deg, Nip roller on second chill, antistatic bar, chill rollers drived by independent servodrives; reel width 2700mm

- Controllo di spessore

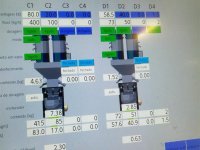

- Automatic, Die with flex lip automatic control through theral expansion bolts, distance between bolts 25,4mm, Thickness gauge Electronic

- Guida film

- Oscillating frame OF2700

- Descrizione avvolgitore

- For machine reels and jumbo reels, Turret automatic winder type W4000/Stretch/3"/6up/650, automatic reels extraction and cores loading, ultra light driven CFP contact roller, TC technology: package to enable core with thin wall thickness(3"cores 3mm and 350 grams)

- Ulteriori informazioni

- Stretch film thicknesses from 8 my up. Complete recycling plant Make starlinger for inline recycling of edges and offline recyling of startups. Output 150-450Kg/h, bimetall barrel and nitrurated screw; water ring system for cuuling and transport; drying centrifuge, reel feeder Winder for jumbo, machine reels

| Codice Macchina | CA155 |

| Manufacturer | SML |

| Year | 2015 |

| Numero di strati | 5 |

| Struttura film | ABCBD |

| Materiali | Stretch film LLDPE |

| Larghezza film (mm) | 2000 |

| Velocità (m/m) | 600 |

| Output (Kg/h) | 1200 |

| Rif strati estrusore 1: | A |

| Screw diam 1 | 60 |

| Description 1 | L/D 28,output 190 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer |

| Rif strati estrusore 2: | B |

| Screw diam 2 | 90 |

| Description 2 | L/D 33,output 600 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer |

| Rif strati estrusore 3: | C |

| Screw diam 3 | 90 |

| Description 3 | L/D 33,output 600 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer |

| Rif strati estrusore 4: | D |

| Screw diam 4 | 60 |

| Description 4 | L/D 28,output 190 KG/H, water cooled AC motor, 3 components gravimetric dosing unit, hydraulic screen changer |

| Descrizione testa | 5 ply feedblock,Automatic die, Bivac vacuum box 2 chamber vacuum box, electrostatic edge pinning with 2 charging electrodes each with 3 fingers max 30 KV , pneumatic edge cooling |

| Die width (mm) | 2550 |

| Unità chill roll | Chill roll unit model 1000/400; diam first chill roll 1000mm; diam second chill roll 400mm; contact lenght first chill roll 240 deg, Nip roller on second chill, antistatic bar, chill rollers drived by independent servodrives; reel width 2700mm |

| Controllo di spessore | Automatic, Die with flex lip automatic control through theral expansion bolts, distance between bolts 25,4mm, Thickness gauge Electronic |

| Guida film | Oscillating frame OF2700 |

| Descrizione avvolgitore | For machine reels and jumbo reels, Turret automatic winder type W4000/Stretch/3"/6up/650, automatic reels extraction and cores loading, ultra light driven CFP contact roller, TC technology: package to enable core with thin wall thickness(3"cores 3mm and 350 grams) |

| Ulteriori informazioni | Stretch film thicknesses from 8 my up. Complete recycling plant Make starlinger for inline recycling of edges and offline recyling of startups. Output 150-450Kg/h, bimetall barrel and nitrurated screw; water ring system for cuuling and transport; drying centrifuge, reel feeder Winder for jumbo, machine reels |

SML

-

Codice Macchina: CA274

-

Year: 2023

-

Larghezza film (mm): 1500

WINDMÖLLER & HÖLSCHER FILMEX

-

Codice Macchina: CA174

-

Year: 2000

-

Larghezza film (mm): 2100

COLINES HANDrollEX 1000A

-

Codice Macchina: CA200

-

Year: 2009

-

Larghezza film (mm): 1000

TECHNO COATING ENGINEERING

-

Codice Macchina: CA060

-

Year: 1997

-

Larghezza film (mm): 1500

DOLCI

-

Codice Macchina: CA194

-

Year: 2011

-

Larghezza film (mm): 2000

WINDMÖLLER & HÖLSCHER FILMEX

-

Codice Macchina: CA093

-

Year: 1995

-

Larghezza film (mm): 1850