- Codice Macchina

- EX763

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- OPTIMEX

- Year

- 2014

- Numero di strati

- 3

- Struttura film

- ABC

- Materiali

- LDPE, LLDPE

- Larghezza film

- 2200

- Rif strati estrusore 1:

- A

- Screw diam 1

- 70.30D - outer layer

- Description 1

- screw speed up to 180 rpm

- Rif strati estrusore 2:

- B

- Screw diam 2

- 90.30D - core layer

- Description 2

- screw speed up to 140 rpm

- Rif strati estrusore 3:

- C

- Screw diam 3

- 70.30D - inner layer

- Description 3

- screw speed up to 180 rpm

- Descrizione testa

- BLOWN FILM DIE HEAD FOR THREE-LAYER FILM TYPE 315/500-3-P2K

- Diamtero filiera (mm)

- 500

- Controllo di spessore

- MODULE G3 - GRAVIMETRIC DOSING AND THROUGHPUT CONTROL for 3 extruders, Brand: Inoex

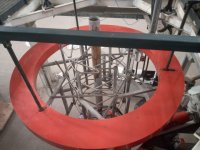

- Bubble cage

- FILM SIZING AND STABILIZING CAGE with coated CFRP rollers, working width: 550 - 2200 mm, precise calibration of the film bubble through accurate adjustment equipment, motorized central tube diameter adjustment and height adjustment, ultrasonic bubble control for highly dynamic direct blower control without mechanical control elements, web break sensor (shut-down of extruders immediately after web break is detected)

- Trattamento Corona

- CORONA-TREATER TYPE L for two-sided treatment of the collapsed tubular film working width: max. 2200 mm, power output: max. 12 kW, dose: 26.09 Wmin/m² at v = 100 m/min, 5 mm segmental electrodes allowing skipping of treatment in web flow direction, ozone extraction including pipes between the treatment station and the extractor fan

- Guida film

- Brand: E+L for a working width of 2200 mm, 2 ultrasonic sensors, electronic sensing system,rotating frame

- Tipo avvolgitore

- Double back to back

- Diametro massimo avvolgitore

- 1200

- Descrizione avvolgitore

- max. reel width -2200mm, max. weight 2500 kg.

- Ulteriori informazioni

- The extruder combination mainly comprises: - direct drive with maintenance-free AC motors and thermally very stable and water-cooled frequency inverters -grooved bush temperature controller for homogenizing of the feed rate depending on the raw material(s) (incl. central water temperature control unit) -low-temperature barrier screw (design: LT, screw length 30D) for an excellent, homogeneous melt quality -screw and feed barrel in long-lasting, low-wear material combination -operation and data display provided at the operator station PROCONTROL Line speed max. - 150 m/min SCREEN CHANGER FANS FOR FILM COOOLING MAGNET SEPARATOR for the extruder combination 70/90/70.30D

| Codice Macchina | EX763 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | OPTIMEX |

| Year | 2014 |

| Numero di strati | 3 |

| Struttura film | ABC |

| Materiali | LDPE, LLDPE |

| Larghezza film | 2200 |

| Rif strati estrusore 1: | A |

| Screw diam 1 | 70.30D - outer layer |

| Description 1 | screw speed up to 180 rpm |

| Rif strati estrusore 2: | B |

| Screw diam 2 | 90.30D - core layer |

| Description 2 | screw speed up to 140 rpm |

| Rif strati estrusore 3: | C |

| Screw diam 3 | 70.30D - inner layer |

| Description 3 | screw speed up to 180 rpm |

| Descrizione testa | BLOWN FILM DIE HEAD FOR THREE-LAYER FILM TYPE 315/500-3-P2K |

| Diamtero filiera (mm) | 500 |

| Controllo di spessore | MODULE G3 - GRAVIMETRIC DOSING AND THROUGHPUT CONTROL for 3 extruders, Brand: Inoex |

| Bubble cage | FILM SIZING AND STABILIZING CAGE with coated CFRP rollers, working width: 550 - 2200 mm, precise calibration of the film bubble through accurate adjustment equipment, motorized central tube diameter adjustment and height adjustment, ultrasonic bubble control for highly dynamic direct blower control without mechanical control elements, web break sensor (shut-down of extruders immediately after web break is detected) |

| Trattamento Corona | CORONA-TREATER TYPE L for two-sided treatment of the collapsed tubular film working width: max. 2200 mm, power output: max. 12 kW, dose: 26.09 Wmin/m² at v = 100 m/min, 5 mm segmental electrodes allowing skipping of treatment in web flow direction, ozone extraction including pipes between the treatment station and the extractor fan |

| Guida film | Brand: E+L for a working width of 2200 mm, 2 ultrasonic sensors, electronic sensing system,rotating frame |

| Tipo avvolgitore | Double back to back |

| Diametro massimo avvolgitore | 1200 |

| Descrizione avvolgitore | max. reel width -2200mm, max. weight 2500 kg. |

| Ulteriori informazioni | The extruder combination mainly comprises: - direct drive with maintenance-free AC motors and thermally very stable and water-cooled frequency inverters -grooved bush temperature controller for homogenizing of the feed rate depending on the raw material(s) (incl. central water temperature control unit) -low-temperature barrier screw (design: LT, screw length 30D) for an excellent, homogeneous melt quality -screw and feed barrel in long-lasting, low-wear material combination -operation and data display provided at the operator station PROCONTROL Line speed max. - 150 m/min SCREEN CHANGER FANS FOR FILM COOOLING MAGNET SEPARATOR for the extruder combination 70/90/70.30D |

GHIOLDI

-

Codice Macchina: EX769

-

Year: 2004

-

Larghezza film: 1500

BIELLONI Coex 3

-

Codice Macchina: EX764

-

Year: 1999

-

Larghezza film: 1700

REIFENHAUSER

-

Codice Macchina: EX808

-

Year: 2022

-

Larghezza film: 1800

MACCHI

-

Codice Macchina: EX748

-

Year: 2002

-

Larghezza film: 2200

DOLCI fIL 700

-

Codice Macchina: EX689

-

Year: 1990

-

Larghezza film: 3200

TECOM EKN90-30D

-

Codice Macchina: EX790

-

Year: 1993

-

Larghezza film: 1800