- Machine code

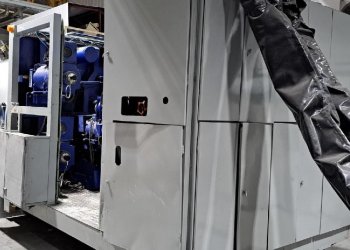

- ME101

- Manufacturer

- BOBST

- Modello

- K5000

- Year

- 2014

- Working width (mm)

- 2450

- Materials

- BOPP10-50my, BOPET8-20my, CPP 20-50my, other films

- Speed

- 1000 m/min

- Max diameter reel unwinder

- 1200mm

- Max diameter reel rewinder

- 1200mm

- Evapouration Boots

- 33 boots, size 125x40x10mm, Aluminium wire 1.6-2.4mm r Alu wire reel diam max 320mm Control: - Individual thrystor controlled transformers controlling power to boots - Individual stepper motors for wire 595mm diam cooled process roll + 250 mm diam post process cooling

- Pumping down time

- less than 5 min in OEM description

- Pumping system

- Operating pressure 5x(10^-4) mBar. Web coating zone: - 1x NC630B dry rotary screw pump, 630m^3/h - 1x Aerzen GM 2000CMC booster pump 3900m^3/h - 2x Varian HS35 diffusion pumps 50.000 l/sec - 1x Polycold PFC. 1102 CE 200 kl/s Web winding zone: - 1x NC630B dry rotary screw pump, 630m^3/h - 1x Aerzen GM 2000CMC booster pump 3900m^3/h - 1x Aerzen GM 8000CMY booster pump 13000m^3/h - 1x extra cryogenic coli unit

- Plasma treatment

- Yes, Max power 4kW/m. 40kHz

- Polycold

- Polycold PFC. 1102 CE 200 kl/s

- Note

- Highlights: - Camera and monitoring system - Portholes circular viewing - Closed loop automatic deposition control - Closed loop tension control - End tensioned evaporator clamping - Precision zones seals - Full width viewing windows - MFC Gas wedge injection system - Individual stepper motor control - Individual temp control - Individual Trystor control - Integrated drum shield and shutter - Inverter controlled booster pumps - Linear tracking anti-telescoping lay-arms - Multi point deposition monitor - Remotely adjustable bowed spread roller - Edge shield adjustment - Same side reel change over - Swing over clamps - Web system control interface Web tension 66-662N Anti telescopio via 2 linear tracking lay arms Cooling: - Process drum: 595mm diam chrome plated - 2 zone gas wedge injection system, layer of gas between process roll and web -1x post coating cooled roller 250 mm diam Spreading: - 1x spiral grooved roll - 3x bowed spread er rollers Tension : - 2x load cell rolls to measure tension on unwind and rewind - 1x Independently driven draw roller, with high friction covering, to tension web over process roll Optical system with light emitting diodes and photo detectors for O.D monitoring Chiller

| Machine code | ME101 |

| Manufacturer | BOBST |

| Modello | K5000 |

| Year | 2014 |

| Working width (mm) | 2450 |

| Materials | BOPP10-50my, BOPET8-20my, CPP 20-50my, other films |

| Speed | 1000 m/min |

| Max diameter reel unwinder | 1200mm |

| Max diameter reel rewinder | 1200mm |

| Evapouration Boots | 33 boots, size 125x40x10mm, Aluminium wire 1.6-2.4mm r Alu wire reel diam max 320mm Control: - Individual thrystor controlled transformers controlling power to boots - Individual stepper motors for wire 595mm diam cooled process roll + 250 mm diam post process cooling |

| Pumping down time | less than 5 min in OEM description |

| Pumping system | Operating pressure 5x(10^-4) mBar. Web coating zone: - 1x NC630B dry rotary screw pump, 630m^3/h - 1x Aerzen GM 2000CMC booster pump 3900m^3/h - 2x Varian HS35 diffusion pumps 50.000 l/sec - 1x Polycold PFC. 1102 CE 200 kl/s Web winding zone: - 1x NC630B dry rotary screw pump, 630m^3/h - 1x Aerzen GM 2000CMC booster pump 3900m^3/h - 1x Aerzen GM 8000CMY booster pump 13000m^3/h - 1x extra cryogenic coli unit |

| Plasma treatment | Yes, Max power 4kW/m. 40kHz |

| Polycold | Polycold PFC. 1102 CE 200 kl/s |

| Note | Highlights: - Camera and monitoring system - Portholes circular viewing - Closed loop automatic deposition control - Closed loop tension control - End tensioned evaporator clamping - Precision zones seals - Full width viewing windows - MFC Gas wedge injection system - Individual stepper motor control - Individual temp control - Individual Trystor control - Integrated drum shield and shutter - Inverter controlled booster pumps - Linear tracking anti-telescoping lay-arms - Multi point deposition monitor - Remotely adjustable bowed spread roller - Edge shield adjustment - Same side reel change over - Swing over clamps - Web system control interface Web tension 66-662N Anti telescopio via 2 linear tracking lay arms Cooling: - Process drum: 595mm diam chrome plated - 2 zone gas wedge injection system, layer of gas between process roll and web -1x post coating cooled roller 250 mm diam Spreading: - 1x spiral grooved roll - 3x bowed spread er rollers Tension : - 2x load cell rolls to measure tension on unwind and rewind - 1x Independently driven draw roller, with high friction covering, to tension web over process roll Optical system with light emitting diodes and photo detectors for O.D monitoring Chiller |

GENERAL VACUUM EQUIPMENT

-

Machine code: ME070

-

Year: 1990

-

Working width (mm): 1980

GALILEO MEGA 2410 A

-

Machine code: ME088

-

Year: 2001

-

Working width (mm): 2450

GENERAL VACUUM EQUIPMENT EHF 1650

-

Machine code: ME103

-

Year: 1994

-

Working width (mm): 1650

GALILEO MEGA 2410

-

Machine code: ME077

-

Year: 2002

-

Working width (mm): 2400

BOBST K5000

-

Machine code: ME104

-

Year: 2007

-

Working width (mm): 2850

GALILEO V8-16/P fLXOMET

-

Machine code: ME090

-

Year: 2006

-

Working width (mm): 1650