- Codice Macchina

- LAB272

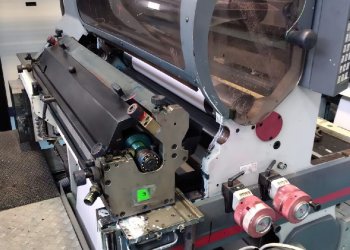

- Manufacturer

- OMET

- Modello

- XFLEX X6 530

- Year

- 2019

- Numero di colori

- 7

- Larghezza nastro (mm)

- 550

- Larghezza stampa (mm)

- 530

- Formato stampa (mm)

- 315 - 508 mm

- Essiccazione

- 7 UV drying sections E2C RHINO LIGHT UV system, power up to 6,6 kW and 3 Heated air drying systems with thermoregulation

- Svolgitore

- - Automatic tension unwinder, for rolls up to 1000 mm (40”) diameter, with integrated roll pick up from the floor. Servo driven infeed section, with automatic web tension control,

- Avvolgitore

- Single shaft rewinder, with independent motor for constant tension control, for rolls up to 1000 mm (40”) diameter, including integrated roll discharge system,

- Ulteriori informazioni

- 3 Flexo units and 4 offset units, 2 die cutting units. SHAFTLESS and GEARLESS Direct Drive flexo printing unit Side registration Servo Motorized; - Automatic Longitudinal and Transverse pre-registration, setting position Web turning bar, sliding on rail Antistatic bars Corona Treater Double side web cleaner 7 closed loop circuitc chilling system for chill drums. Automatic wash-up system for the offset inking train, complete with nozzles, washing detergents supply driven by electro-valves, liquid tank next to the relevant offset printing station, cleaning-roll doctor blade and solvent recycling tray. Printing Tooling (sleeve and cams) repeat: 99;104;128;134;144;146;149;153;156;157;160 Z;

| Codice Macchina | LAB272 |

| Manufacturer | OMET |

| Modello | XFLEX X6 530 |

| Year | 2019 |

| Numero di colori | 7 |

| Larghezza nastro (mm) | 550 |

| Larghezza stampa (mm) | 530 |

| Formato stampa (mm) | 315 - 508 mm |

| Essiccazione | 7 UV drying sections E2C RHINO LIGHT UV system, power up to 6,6 kW and 3 Heated air drying systems with thermoregulation |

| Svolgitore | - Automatic tension unwinder, for rolls up to 1000 mm (40”) diameter, with integrated roll pick up from the floor. Servo driven infeed section, with automatic web tension control, |

| Avvolgitore | Single shaft rewinder, with independent motor for constant tension control, for rolls up to 1000 mm (40”) diameter, including integrated roll discharge system, |

| Ulteriori informazioni | 3 Flexo units and 4 offset units, 2 die cutting units. SHAFTLESS and GEARLESS Direct Drive flexo printing unit Side registration Servo Motorized; - Automatic Longitudinal and Transverse pre-registration, setting position Web turning bar, sliding on rail Antistatic bars Corona Treater Double side web cleaner 7 closed loop circuitc chilling system for chill drums. Automatic wash-up system for the offset inking train, complete with nozzles, washing detergents supply driven by electro-valves, liquid tank next to the relevant offset printing station, cleaning-roll doctor blade and solvent recycling tray. Printing Tooling (sleeve and cams) repeat: 99;104;128;134;144;146;149;153;156;157;160 Z; |

GALLUS TCS 250

-

Codice Macchina: LAB247

-

Year: 2006

-

Larghezza nastro (mm): 250

OMET X flex X6

-

Codice Macchina: LAB269

-

Year: 2013

-

Larghezza nastro (mm):

LOMBARDI FLEXOLINE 330

-

Codice Macchina: LAB241

-

Year: 2009

-

Larghezza nastro (mm): 350

OMET FLEX x6

-

Codice Macchina: LAB254

-

Year: 2008

-

Larghezza nastro (mm): 430

ETI Metronome 1308

-

Codice Macchina: LAB210

-

Year: 2003

-

Larghezza nastro (mm): 335

OMET Varyflex V1

-

Codice Macchina: LAB270

-

Year: 2011

-

Larghezza nastro (mm):