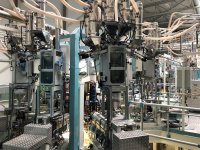

- Code Machine

- TB9

- Fabricant

- KUHNE

- Année

- 2011

- Number of layers

- 9

- Film structure

- ABCDEFGHI Typical structure: PO (5%) - HV (5%) - PO (35%) - HV (5%) - PA (5%) – EVOH (5%) - PA (5%) - HV (5%) – PO (30%) Machine is also designed for structures with PET

- Material

- 9 layers barrier and shrink film structures with PO (PE, PP and another polyolefins)/PA/EVOH/PET

- Output

- max 140-160 Kg

- Film width (mm)

- 700

- Extruders

- 9 extruders: A- Screw diam 35mm L/D24, AC Motor, approx. 20 Kg/h with PO (PE and PP) and PET 5 comp FDM doser ; B- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with HV 3 comp FDM doser; C- Screw diam 60mm L/D24, AC Motor, approx. 90 Kg/h with PO, 70 Kg/h with PA; 3 comp FDM doser D- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with HV; 2 comp FDM doser E- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with PA 3 comp FDM doser; F- Screw diam 35mm L/D24, AC Motor, approx. 15 Kg/h with EVOH 2 comp FDM doser; G- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with PA 3 comp FDM doser; H- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with HV 2 comp FDM doser; I- Screw diam 45mm L/D24, AC Motor, approx. 60 Kg/h with PO 5 comp FDM doser- Melt Gear Pumps after all extruders - hydraulic screen changer

- Head

- 9-layer extrusion die with 2 die inserts 80 mm and 160mm die

- Stretching

- Triple bubble line, see details in Additional information section

- Rewinder

- Automatic single winder. Max width 700mm, max reel diam 800mm, max speed 100m/min

- Note

- Stretching: - preforming unit gage insert 1 set -1st pulling unit max speed 40m/min: for pulling and tension control - Preheating exchange length 3m - 2nd pulling unit max speed 40m/min: Squeezing the film tube, 2 squeezing rollers - Cooling ring for process stabilizing after preheating and pulling (including heat exchanger) - Cooling ring for cooling (including heat exchanger) -3rd pulling unit max speed 100m/min: to pull tubular, Reversing device and air reversing layers Reverse speed infinitely adjustable, Electric height level adjustment Adjustment range 2m - Width gauge - Humidification pool - Blowing off - 4th Pulling unit max speed 100m/min: to pull material from unit 3, and to guide material into post-treatment unit - Post treatment - Corona treatment - Dancing roller - Width gauge Dosing system: - 5 x gravimetric dosing units 3 components for extruders A/C/E/G/I - 4 x gravimetric dosing units 3 components for extruders B/D/F/H Material suction system Thermoregulation units

| Code Machine | TB9 |

| Fabricant | KUHNE |

| Année | 2011 |

| Number of layers | 9 |

| Film structure | ABCDEFGHI Typical structure: PO (5%) - HV (5%) - PO (35%) - HV (5%) - PA (5%) – EVOH (5%) - PA (5%) - HV (5%) – PO (30%) Machine is also designed for structures with PET |

| Material | 9 layers barrier and shrink film structures with PO (PE, PP and another polyolefins)/PA/EVOH/PET |

| Output | max 140-160 Kg |

| Film width (mm) | 700 |

| Extruders | 9 extruders: A- Screw diam 35mm L/D24, AC Motor, approx. 20 Kg/h with PO (PE and PP) and PET 5 comp FDM doser ; B- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with HV 3 comp FDM doser; C- Screw diam 60mm L/D24, AC Motor, approx. 90 Kg/h with PO, 70 Kg/h with PA; 3 comp FDM doser D- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with HV; 2 comp FDM doser E- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with PA 3 comp FDM doser; F- Screw diam 35mm L/D24, AC Motor, approx. 15 Kg/h with EVOH 2 comp FDM doser; G- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with PA 3 comp FDM doser; H- Screw diam 30mm L/D24, AC Motor, approx. 10 Kg/h with HV 2 comp FDM doser; I- Screw diam 45mm L/D24, AC Motor, approx. 60 Kg/h with PO 5 comp FDM doser- Melt Gear Pumps after all extruders - hydraulic screen changer |

| Head | 9-layer extrusion die with 2 die inserts 80 mm and 160mm die |

| Stretching | Triple bubble line, see details in Additional information section |

| Rewinder | Automatic single winder. Max width 700mm, max reel diam 800mm, max speed 100m/min |

| Note | Stretching: - preforming unit gage insert 1 set -1st pulling unit max speed 40m/min: for pulling and tension control - Preheating exchange length 3m - 2nd pulling unit max speed 40m/min: Squeezing the film tube, 2 squeezing rollers - Cooling ring for process stabilizing after preheating and pulling (including heat exchanger) - Cooling ring for cooling (including heat exchanger) -3rd pulling unit max speed 100m/min: to pull tubular, Reversing device and air reversing layers Reverse speed infinitely adjustable, Electric height level adjustment Adjustment range 2m - Width gauge - Humidification pool - Blowing off - 4th Pulling unit max speed 100m/min: to pull material from unit 3, and to guide material into post-treatment unit - Post treatment - Corona treatment - Dancing roller - Width gauge Dosing system: - 5 x gravimetric dosing units 3 components for extruders A/C/E/G/I - 4 x gravimetric dosing units 3 components for extruders B/D/F/H Material suction system Thermoregulation units |

KUHNE

-

Code Machine: TB15

-

Année: 2008

-

Film width (mm): 500

TECHNO COATING ENGINEERING

-

Code Machine: TB17

-

Année: 2000

-

Film width (mm): 2500

TECNOVA

-

Code Machine: TB5

-

Année: 1990

-

Film width (mm): 1780