Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

- Machine Code

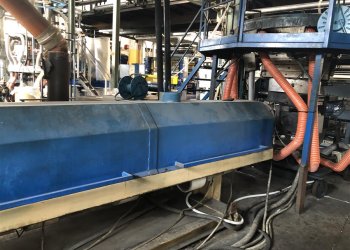

- EX289

- Manufacturer

- TECHNO COATING ENGINEERING

- Year

- 2001

- Number of layers

- 3

- Overhaul/renovation

- Renovation 2011, new screw and barrel.

- Film structure

- ABC

- Film Width

- 2200

- Output (Kg/h)

- 350-400 Kg/h

- Screw diam 1

- 90

- Description 1

- DC motor ABB ; Gravimetric dosing unit Inoex , 4 components

- Screw diam 2

- 120

- Description 2

- DC motor ABB; Gravimetric dosing unit Inoex , 3 components

- Screw diam 3

- 90

- Description 3

- DC motor ABB ; Gravimetric dosing unit Inoex , 4 components

- Head description

- Make Macro Engineering (Canada), Gap 2,2; IBC

- Die diam (mm)

- 500 mm

- Thickness controll system

- Automatic thickness control system Plastcontrol year 2002 ;Thickness gauge Plascontroll; automatic cooling ring Plastcontrol, 72 blowing units; IBC; Microperforator;

- Bubble cage

- Automatic buble guide Reinolds 4 sensors;

- Panel for gussets

- No

- Take off unit

- Oscillating take off unit Make Reinolds

- Corona treatment

- 3 corona treater Cason

- Web guide

- yes

- Rewinder Type

- Double back to back

- Rewinder description

- Rewinder Tecno Coating. Drive of winding axial or Gap. Complete with 4 espansive shafts diam 152 ; 4 espansive shafts diam 76mm.

- Note

- Microperforator;

| Machine Code | EX289 |

| Manufacturer | TECHNO COATING ENGINEERING |

| Year | 2001 |

| Number of layers | 3 |

| Overhaul/renovation | Renovation 2011, new screw and barrel. |

| Film structure | ABC |

| Film Width | 2200 |

| Output (Kg/h) | 350-400 Kg/h |

| Screw diam 1 | 90 |

| Description 1 | DC motor ABB ; Gravimetric dosing unit Inoex , 4 components |

| Screw diam 2 | 120 |

| Description 2 | DC motor ABB; Gravimetric dosing unit Inoex , 3 components |

| Screw diam 3 | 90 |

| Description 3 | DC motor ABB ; Gravimetric dosing unit Inoex , 4 components |

| Head description | Make Macro Engineering (Canada), Gap 2,2; IBC |

| Die diam (mm) | 500 mm |

| Thickness controll system | Automatic thickness control system Plastcontrol year 2002 ;Thickness gauge Plascontroll; automatic cooling ring Plastcontrol, 72 blowing units; IBC; Microperforator; |

| Bubble cage | Automatic buble guide Reinolds 4 sensors; |

| Panel for gussets | No |

| Take off unit | Oscillating take off unit Make Reinolds |

| Corona treatment | 3 corona treater Cason |

| Web guide | yes |

| Rewinder Type | Double back to back |

| Rewinder description | Rewinder Tecno Coating. Drive of winding axial or Gap. Complete with 4 espansive shafts diam 152 ; 4 espansive shafts diam 76mm. |

| Note | Microperforator; |

DOLCI fIL 700

-

Machine Code: EX689

-

Year: 1990

-

Film Width: 3200

BATTENFELD

-

Machine Code: EX512

-

Year: 2003

-

Film Width: 2200

REIFENHAUSER

-

Machine Code: EX732

-

Year: 1999

-

Film Width: 1600