Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

- Machine Code

- CA168

- Manufacturer

- TECHNO COATING ENGINEERING

- Year

- 1999

- Number of layers

- 5

- Film structure

- A/C/B/C/D

- Material

- Stretch film LLDPE

- Film width (mm)

- 3000

- Speed (m/min)

- 450 mt/min - (max 600 mt/min)

- Output (Kg/h)

- 1650 and 1700 Kg/h

- Head description

- EDI

- Die width (mm)

- 3700 mm

- Chill roll unit

- 2 cylinders of diam 980 mm and diam 450 mm

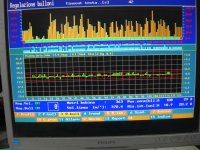

- Thickness controll system

- Yes

- Web guide

- Yes

- Rewinder max reel diameter (mm)

- 600

- Rewinder description

- Dual 1500mm each.

- Note

- PLC - SIEMENS S7/400 Power - 2800 Kw

| Machine Code | CA168 |

| Manufacturer | TECHNO COATING ENGINEERING |

| Year | 1999 |

| Number of layers | 5 |

| Film structure | A/C/B/C/D |

| Material | Stretch film LLDPE |

| Film width (mm) | 3000 |

| Speed (m/min) | 450 mt/min - (max 600 mt/min) |

| Output (Kg/h) | 1650 and 1700 Kg/h |

| Head description | EDI |

| Die width (mm) | 3700 mm |

| Chill roll unit | 2 cylinders of diam 980 mm and diam 450 mm |

| Thickness controll system | Yes |

| Web guide | Yes |

| Rewinder max reel diameter (mm) | 600 |

| Rewinder description | Dual 1500mm each. |

| Note | PLC - SIEMENS S7/400 Power - 2800 Kw |

TECHNO COATING ENGINEERING

-

Machine Code: CA163

-

Year: 1993

-

Film width (mm): 2000

WINDMÖLLER & HÖLSCHER FILMATIC M

-

Machine Code: CA181

-

Year: 1998

-

Film width (mm): 1600

COLINES AllRollEx

-

Machine Code: CA202

-

Year: 2016

-

Film width (mm): 1500

WINDMÖLLER & HÖLSCHER FILMEX

-

Machine Code: CA133

-

Year: 1999

-

Film width (mm): 1760

WINDMÖLLER & HÖLSCHER FILMEX

-

Machine Code: CA093

-

Year: 1995

-

Film width (mm): 1850