** SOLD **

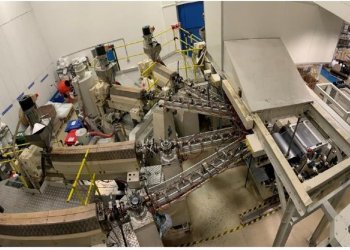

Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

about a similar one

- Machine Code

- CA154

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- FILMEX

- Year

- 2012

- Number of layers

- 9

- Material

- CPP and Barrier Film

- Film width (mm)

- 2400

- Speed (m/min)

- 350

- Output (Kg/h)

- 1000 gross

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 135

- Description 1

- FILMEX

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 90

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 90

- Extruder 4 Layer ref:

- D

- Screw diam 4

- 70

- Extruder 5 Layer ref:

- E

- Screw diam 5

- 60

- Extruder 6 Layer ref:

- F

- Screw diam 6

- 50

- Extruder 7 Layer ref:

- G

- Screw diam 7

- 50

- Head description

- automatic die 2700 mm wide Coeren with feed block for 9 layers, dual chamber vacuum box , internal slot die deckling system with edge encapsulation

- Die width (mm)

- 2700

- Chill roll unit

- double chill roller , electrostatic edge stabilization pneumatic edge stabilization

- Thickness controll system

- Infrared thickness gauge NDC with additio nal infrared gauge

- Corona treatment

- Yes, for pre treatment

- Rewinder max reel diameter (mm)

- 1200

- Rewinder description

- Center driven

- Note

- Total electrical connected load: 1350 KVA Power: 400V/50Hz 1000 kw installed power

| Machine Code | CA154 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | FILMEX |

| Year | 2012 |

| Number of layers | 9 |

| Material | CPP and Barrier Film |

| Film width (mm) | 2400 |

| Speed (m/min) | 350 |

| Output (Kg/h) | 1000 gross |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 135 |

| Description 1 | FILMEX |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 90 |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 90 |

| Extruder 4 Layer ref: | D |

| Screw diam 4 | 70 |

| Extruder 5 Layer ref: | E |

| Screw diam 5 | 60 |

| Extruder 6 Layer ref: | F |

| Screw diam 6 | 50 |

| Extruder 7 Layer ref: | G |

| Screw diam 7 | 50 |

| Head description | automatic die 2700 mm wide Coeren with feed block for 9 layers, dual chamber vacuum box , internal slot die deckling system with edge encapsulation |

| Die width (mm) | 2700 |

| Chill roll unit | double chill roller , electrostatic edge stabilization pneumatic edge stabilization |

| Thickness controll system | Infrared thickness gauge NDC with additio nal infrared gauge |

| Corona treatment | Yes, for pre treatment |

| Rewinder max reel diameter (mm) | 1200 |

| Rewinder description | Center driven |

| Note | Total electrical connected load: 1350 KVA Power: 400V/50Hz 1000 kw installed power |

REIFENHAUSER

-

Machine Code: CA248

-

Year: 1991

-

Film width (mm): 1550

WINDMÖLLER & HÖLSCHER FILMEX

-

Machine Code: CA246

-

Year: 2015

-

Film width (mm): 2700

WINDMÖLLER & HÖLSCHER FILMATIC M

-

Machine Code: CA181

-

Year: 1998

-

Film width (mm): 1600